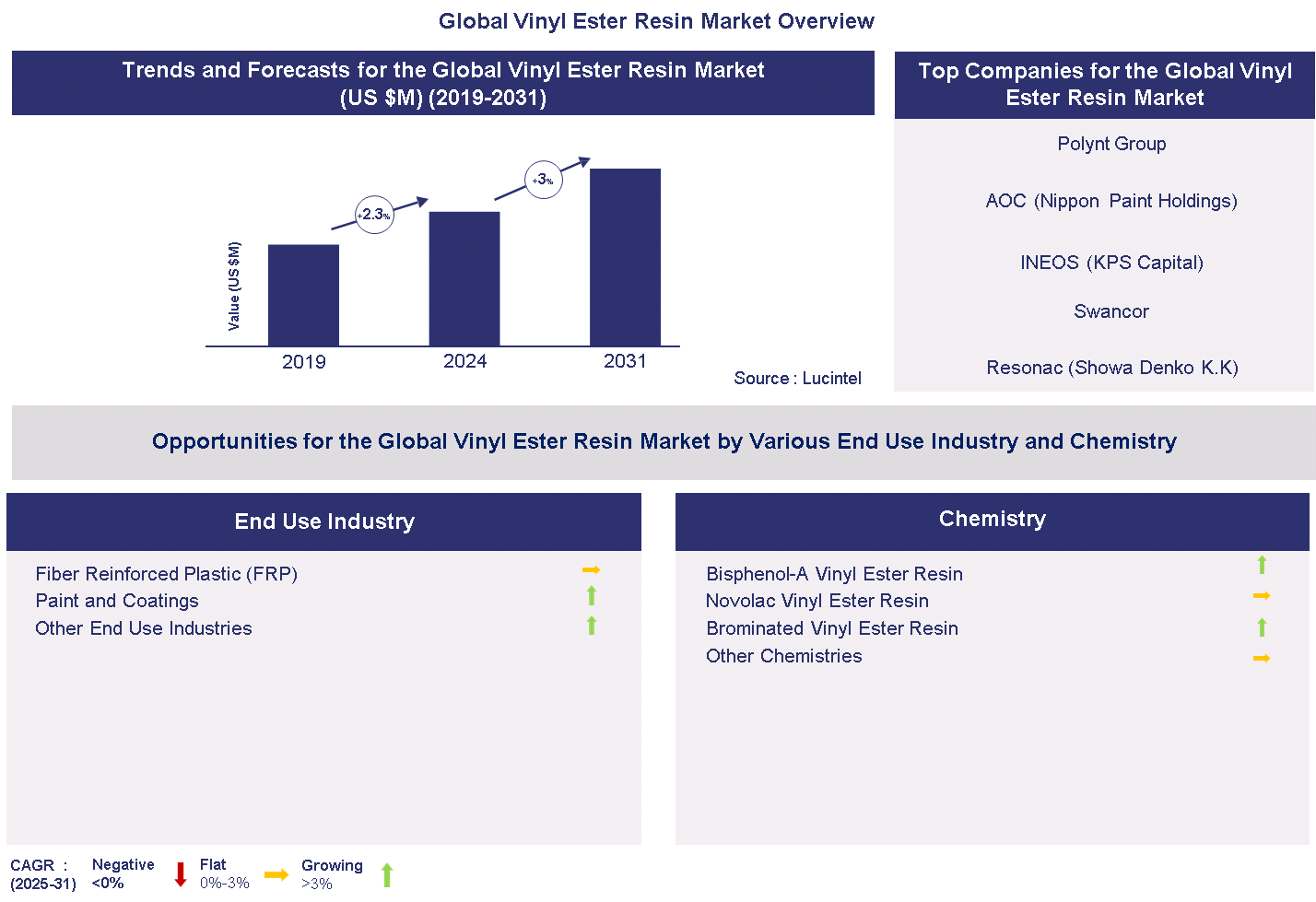

Vinyl Ester Resin Market Trends and Forecasts

Lucintel finds that the future of the global vinyl ester resin material market looks promising with opportunities in the FRP, paint and coatings and other applications. The global vinyl ester resin market is expected to grow at a CAGR of 3.4% from 2024 to 2031. The major drivers for this market are increasing demand for corrosion resistance materials, growing infrastructural investments, and rehabilitation of old infrastructural projects.

Unsaturated carboxylic acids such as methacrylic acid and acrylic acid, and epoxides such as bisphenol-A diglycidyl ether are primarily converted into vinyl ester resins. Styrene or other reactive diluents help to control the viscosity of the resin and ease its polymerization. Curing agents such as peroxides stimulate crosslinking and fillers or additives improve resin properties. The price of vinyl ester resin is generally higher compared to traditional unsaturated polyester resins due to its superior properties and performance. However, it remains competitive with specialty resins and composites, offering advantages in durability and resistance that can justify the higher cost in niche applications.

• Bisphenol-A vinyl ester resin will remain the largest segment over the forecast period due to its good mechanical and chemical resistance properties at a relatively lower cost and it is also expected to witness highest growth over the forecast period.

• Pipe and tanks will remain the largest application segment over the forecast period due to the due to the significant demands from industries such as oil and gas, wastewater, sewage, chemical, retail fuel, and pulp/paper.

• Asia Pacific is expected to remain the largest region over the forecast period because of the tremendous economic growth in China and India, and increasing demand for corrosion resistance pipe and tanks and growing investment in the building and construction and well as industrial sector and it is also expected to the witness highest growth over the forecast period.

Country wise Outlook for the Vinyl Ester Resin Market

The global vinyl ester resin market is witnessing substantial growth globally. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major vinyl ester resin producers in key regions/countries: the USA, Germany, China, and India.

Emerging Trends in the Vinyl Ester Resin Market

The vinyl ester resin market is experiencing significant growth due to its unique properties and versatility in various applications, including construction, automotive, and marine industries. As industries seek materials that offer durability, chemical resistance, and lightweight characteristics, vinyl ester resins are becoming increasingly popular. This growth is further fueled by advancements in manufacturing technologies and a rising demand for sustainable materials. The following are five key emerging trends in the vinyl ester resin market that are shaping its future and influencing consumer preferences and industry standards.

• Increased Demand for Sustainable Materials: The shift towards eco-friendly products is driving manufacturers to develop bio-based vinyl ester resins. These sustainable alternatives reduce environmental impact while maintaining performance, appealing to environmentally conscious consumers and industries. This trend is prompting companies to innovate and invest in greener production processes, ultimately reshaping the market landscape.

• Advancements in Manufacturing Technologies: Innovations in production techniques, such as improved curing processes and enhanced formulations, are leading to higher quality vinyl ester resins. These advancements allow for better performance characteristics, such as increased strength and durability, making vinyl ester resins more competitive against traditional materials. As technology continues to evolve, manufacturers can meet diverse customer needs more effectively.

• Growth in the Marine Industry: The marine sector is increasingly adopting vinyl ester resins due to their excellent resistance to water and chemicals. This trend is driven by the need for lightweight, durable materials that can withstand harsh marine environments. As boat manufacturers seek to enhance performance and longevity, the demand for vinyl ester resins is expected to rise significantly in this sector.

• Expansion in the Automotive Sector: The automotive industry is recognizing the benefits of vinyl ester resins for lightweighting and improving fuel efficiency. As regulations on emissions become stricter, manufacturers are turning to these resins to create lighter components without compromising safety or performance. This trend is likely to accelerate the adoption of vinyl ester resins in automotive applications, driving market growth.

• Rising Investment in Research and Development: Increased investment in R&D is fostering innovation in vinyl ester resin formulations and applications. Companies are exploring new uses and improving existing products to meet evolving market demands. This trend is crucial for maintaining competitiveness and addressing challenges such as performance limitations and environmental concerns, ultimately leading to a more dynamic market.

These emerging trends are significantly reshaping the vinyl ester resin market by promoting sustainability, enhancing manufacturing processes, and expanding applications across various industries. As companies adapt to these changes, the market is likely to see increased competition, innovation, and a stronger focus on meeting consumer demands.

Recent Developments in the Vinyl Ester Resin Market

The vinyl ester resin market has experienced significant growth and transformation in recent years, driven by advancements in technology, increasing demand across various industries, and a growing emphasis on sustainability. Vinyl ester resins, known for their superior mechanical properties and resistance to corrosion, are widely used in applications such as marine, automotive, and construction. Recent developments in this market reflect a shift towards innovative formulations, enhanced production processes, and a focus on eco-friendly solutions. Below are five key developments that are shaping the future of the vinyl ester resin market.

• Expansion of Applications: The increasing use of vinyl ester resins in the automotive and aerospace industries is driving market growth. Their lightweight and durable properties make them ideal for manufacturing components that require high strength-to-weight ratios, leading to improved fuel efficiency and performance in vehicles.

• Technological Advancements: Innovations in production techniques, such as the development of advanced curing systems, have enhanced the efficiency and quality of vinyl ester resins. These advancements allow for faster curing times and improved mechanical properties, making the resins more appealing to manufacturers seeking to optimize their production processes.

• Sustainability Initiatives: There is a growing trend towards the use of bio-based vinyl ester resins, which are derived from renewable resources. This shift not only reduces the environmental impact of resin production but also meets the increasing consumer demand for sustainable materials, positioning companies favorably in a competitive market.

• Strategic Partnerships: Collaborations between resin manufacturers and end-users are becoming more common, facilitating the development of customized solutions that meet specific industry needs. These partnerships enable companies to leverage each other‘s expertise, resulting in innovative products that enhance performance and application versatility.

• Regulatory Compliance: Stricter environmental regulations are prompting manufacturers to reformulate their products to comply with safety and environmental standards. This has led to the development of low-VOC and non-toxic vinyl ester resins, which not only meet regulatory requirements but also appeal to environmentally conscious consumers.

These developments are significantly impacting the vinyl ester resin market by expanding application areas, enhancing production efficiency, promoting sustainability, fostering innovation through partnerships, and ensuring compliance with regulations. As a result, the market is poised for continued growth, driven by the demand for high-performance, eco-friendly materials.

Strategic Growth Opportunities for the Vinyl Ester Resin Market

The vinyl ester resin market is experiencing significant growth due to its superior properties, including corrosion resistance, thermal stability, and mechanical strength. These characteristics make vinyl ester resins ideal for various applications, particularly in industries such as marine, automotive, construction, and aerospace. As demand for lightweight and durable materials increases, several strategic growth opportunities are emerging across key applications. This analysis highlights five key growth opportunities that are poised to drive market expansion and innovation in the vinyl ester resin sector.

• Marine Industry: The marine sector is increasingly adopting vinyl ester resins for boat manufacturing and repair due to their excellent resistance to water and chemicals. This trend is driven by the need for durable materials that can withstand harsh marine environments, leading to longer-lasting vessels and reduced maintenance costs.

• Automotive Applications: The automotive industry is leveraging vinyl ester resins for lightweight components, enhancing fuel efficiency and performance. As manufacturers focus on reducing vehicle weight to meet stringent emissions regulations, the demand for these resins is expected to rise, fostering innovation in composite materials.

• Construction Sector: In construction, vinyl ester resins are gaining traction for their use in high-performance composites and coatings. Their ability to provide superior durability and resistance to environmental factors makes them ideal for infrastructure projects, thus driving growth in this application as urbanization continues to expand.

• Wind Energy: The wind energy sector is turning to vinyl ester resins for turbine blade manufacturing due to their excellent mechanical properties and resistance to environmental degradation. As the demand for renewable energy sources increases, the use of these resins in wind energy applications is anticipated to expand, contributing to market growth.

The vinyl ester resin market is poised for substantial growth driven by strategic opportunities across various applications. The increasing demand for durable, lightweight materials in marine, automotive, construction, and wind energy sectors is shaping the future of this market, leading to innovations and enhanced product offerings.

Vinyl Ester Resin Market Drivers and Challenges

The vinyl ester resin market is influenced by a variety of technological, economic, and regulatory factors that drive its growth and present challenges. As industries increasingly seek durable and corrosion-resistant materials, vinyl ester resins have gained popularity in applications ranging from construction to automotive. However, the market also faces hurdles such as fluctuating raw material prices and stringent environmental regulations. Understanding these drivers and challenges is crucial for stakeholders aiming to navigate the complexities of this evolving market landscape.

The key drivers for this market include:

• Increasing Demand for Lightweight Materials: The automotive and aerospace industries are shifting towards lightweight materials to enhance fuel efficiency, driving the demand for vinyl ester resins.

• Growth in the Construction Sector: The rising construction activities globally, particularly in emerging economies, are boosting the demand for vinyl ester resins due to their superior mechanical properties and resistance to chemicals.

• Advancements in Manufacturing Technologies: Innovations in production processes, such as improved curing techniques, are enhancing the performance and application scope of vinyl ester resins, making them more attractive to manufacturers.

• Rising Awareness of Environmental Sustainability: The push for eco-friendly materials is leading to increased adoption of vinyl ester resins, which can be formulated to be less harmful to the environment compared to traditional resins.

• Expanding Applications in Various Industries: The versatility of vinyl ester resins allows for their use in diverse applications, including marine, automotive, and electrical sectors, further driving market growth.

The challenges facing this market include:

• Volatility in Raw Material Prices: Fluctuations in the prices of key raw materials used in vinyl ester resin production can impact profit margins and pricing strategies for manufacturers.

• Stringent Regulatory Frameworks: Increasingly strict environmental regulations regarding the production and disposal of resins can pose compliance challenges for manufacturers, potentially leading to increased costs.

• Competition from Alternative Materials: The emergence of alternative materials, such as thermoplastics and bio-based resins, presents a competitive challenge to vinyl ester resins, as industries may opt for these alternatives for specific applications.

The vinyl ester resin market is shaped by significant drivers such as the demand for lightweight materials and advancements in manufacturing technologies, which foster growth. However, challenges like raw material price volatility and regulatory pressures can hinder progress. Stakeholders must strategically navigate these dynamics to capitalize on opportunities while mitigating risks, ensuring sustainable growth in this competitive landscape.

List of Vinyl Ester Resin Companies

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies vinyl ester resin companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the vinyl ester resin companies profiled in this report include.

• Polynt Group

• INEOS Composites (KPS Capital)

• AOC (Nippon Paint Holdings Co., Ltd)

• Swancor Ind. Co., Ltd.

• Resonac (Showa Denko K.K)

• Sino Polymer Co., Ltd.

• Scott Bader Co. Ltd.

• Allnex (PTT Global Chemical Group)

These companies have established themselves as leaders in the global vinyl ester resin market, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the vinyl ester resin market are evolving, with the entry of new players and the emergence of innovative vinyl ester resin market technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Vinyl Ester Resin Market by Segment

The major growing segments of the vinyl ester resin market are marine applications due to their excellent corrosion resistance; chemical processing where they must endure in a harsh environment and infrastructure projects for their strength and longevity. The automotive and aerospace industries also seek lightweight and high-performance components made from vinyl ester resins, driven by the need for fuel efficiency and advanced engineering solutions.

The study includes a forecast for the global vinyl ester resin market by application , chemistry, and region as follows:

By Application [Value ($M) and Volume (M lbs.) Analysis for 2019 – 2031]:

• Fiber Reinforced Plastic (FRP)

• Pipes and tanks

• Construction

• Transportation

• Other End Uses

• Paint and Coatings

• Other Applications

By Chemistry [Value ($M) and Volume (M lbs.) Analysis for 2019 – 2031]:

• Bisphenol-A Vinyl Ester Resin

• Novolac Vinyl Ester Resin

• Brominated Vinyl Ester Resin

• Other Chemistries

By Region [Value ($M) and Volume (M lbs.) Analysis for 2019 – 2031]:

• North America

• The US

• Canada

• Europe

• Germany

• United Kingdom

• France

• Asia Pacific

• China

• India

• Japan

• Rest of the World

• Brazil

Features of Vinyl Ester Resin Market

• Market Size Estimates: Vinyl ester resin market size estimation in terms of value ($M) and Volume (M lbs.).

• Trend and Forecast Analysis: Market trends (2019-2024) and forecast (2025-2031) by various segments and regions.

• Segmentation Analysis: Market size by chemistry, application, and region.

• Regional Analysis: Vinyl ester resin market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different application, chemistry, and regions for the vinyl ester resin market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the vinyl ester resin market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in high performance glass fiber or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the growth forecast for vinyl ester resin market?

Answer: The vinyl ester resin market is expected to grow at a CAGR of 3.4% from 2024 to 2031.

Q2. What are the major drivers influencing the growth of the vinyl ester resin market?

Answer: The major drivers for this market are increasing demand for corrosion resistance materials, growing infrastructural investments, and rehabilitation of old infrastructural projects.

Q3. What are the major applications or end use industries for vinyl ester resin?

Answer: FRP and paints & coatings are the major applications for vinyl ester resin.

Q4. What are the emerging trends in vinyl ester resin market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include increased demand for sustainable materials, advancements in manufacturing technologies, growth in the marine industry, and expansion in the automotive sector.

Q5. Who are the key vinyl ester resin companies?

Answer: Some of the key vinyl ester resin companies are as follows:

• Polynt Group

• INEOS Composites (KPS Capital)

• AOC (Nippon Paint Holdings Co., Ltd)

• Swancor Ind. Co., Ltd.

• Resonac (Showa Denko K.K.)

• Sino Polymer Co., Ltd.

• Scott Bader Co. Ltd.

• Allnex (PTT Global Chemical Group)

Q6. Which vinyl ester resin product segment will be the largest in future?

Answer: Lucintel forecasts that bisphenol-A vinyl ester resin will remain the largest segment over the forecast period due to its good mechanical and chemical resistance properties at a relatively lower cost

Q7. In vinyl ester resin market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 7 years

Q8. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions:

Q.1 What are some of the most promising potential, high growth opportunities for the global vinyl ester resin market by application (FRP, paint and coatings and other applications), chemistry (bisphenol-A vinyl ester resin, novolac vinyl ester resin, brominated vinyl ester resin, and other chemistries), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?