Vacuum Quick Fitting Market Trends and Forecast

The technologies in the vacuum quick fitting market have undergone significant changes in recent years, with advancements from quick-release locking technology to push-to-connect and vacuum sealing technologies. These shifts are improving efficiency, flexibility, and ease of use in various industries such as food and medicine. The introduction of push-to-connect systems has made installation faster and more convenient, eliminating the need for tools or complex assembly processes. Vacuum sealing technologies have become more reliable, ensuring better product integrity and safety, particularly in applications where sterility is critical, such as in the food and pharmaceutical industries. High-pressure resistance fittings have also seen enhancements, allowing for more durable solutions under extreme conditions. Overall, these technological shifts reflect the growing need for speed, ease of use, and performance in vacuum quick fitting applications across various sectors.

Emerging Trends in the Vacuum Quick Fitting Market

The vacuum quick fitting market is evolving rapidly, driven by technological innovation and industry demands. The following emerging trends are shaping the market:

• Increased automation and efficiency: Automation in industries like food and medicine is pushing demand for fast, reliable vacuum quick fittings that improve operational efficiency.

• Growth in medical and pharmaceutical applications: The demand for sterility and precision in vacuum systems is increasing, especially in pharmaceutical manufacturing.

• Compact and modular designs: Manufacturers are focusing on compact, modular fittings to enable easier integration into automated systems, particularly in food production lines.

• Integration of advanced sealing technologies: Innovations in vacuum sealing technologies are improving the airtight integrity of systems, particularly in industries requiring sterile environments.

• Sustainability and eco-friendly materials: Manufacturers are focusing on producing fittings using sustainable materials that offer better environmental performance without sacrificing strength or durability.

These trends highlight how vacuum quick fitting technologies are becoming increasingly vital in sectors requiring efficiency, precision, and hygiene. As demand for automation and eco-friendly solutions grows, these trends will continue to shape the market, ensuring higher functionality and adaptability.

Vacuum Quick Fitting Market : Industry Potential, Technological Development, and Compliance Considerations

The vacuum quick fitting market is evolving with significant technological advancements, especially in industries such as food processing, pharmaceuticals, and manufacturing. Technologies like quick-release locking, push-to-connect, vacuum sealing, and high-pressure resistance fittings are reshaping how industrial processes are carried out, offering solutions that improve operational efficiency, safety, and reliability.

• Technology Potential:

The potential for vacuum quick fittings to transform industries is immense, particularly in food and medical sectors where hygiene, efficiency, and reliability are crucial. Push-to-connect and vacuum sealing technologies enhance automation by reducing the need for manual intervention, improving assembly times, and ensuring contamination-free environments. In sectors like pharmaceuticals, vacuum sealing provides a sterile barrier for sensitive materials, ensuring product integrity during processing and transport. Additionally, high-pressure resistance fittings are making their way into heavy-duty industrial applications, offering durable solutions for extreme conditions. The growth potential is significant, especially with automation and IoT integration.

• Degree of Disruption:

These technologies significantly disrupt traditional assembly and sealing processes by reducing labor costs, minimizing human error, and streamlining production. Push-to-connect and quick-release locking systems particularly impact the assembly line by providing faster installation and ease of maintenance. With automation and robotics adoption on the rise, vacuum quick fittings play a pivotal role in increasing the speed and reliability of automated systems.

• Level of Current Technology Maturity:

Technologies like push-to-connect and vacuum sealing are already well-established in the market, with applications spanning across various industries. However, high-pressure resistance fittings are still evolving, with innovations in material science driving their ongoing development for more challenging environments. While many of these technologies have reached a degree of maturity, continuous advancements in material strength, flexibility, and functionality are driving further improvements.

• Regulatory Compliance:

The vacuum quick fitting market is subject to rigorous regulations, particularly in the food and pharmaceutical sectors, where hygiene, product safety, and contamination prevention are paramount. Fittings must adhere to strict quality standards to ensure safe and reliable use in critical environments. Compliance with local and international regulations, such as ISO standards for materials, is essential for manufacturers to succeed in these highly regulated industries.

In conclusion, vacuum quick fittings are revolutionizing industries with their ability to improve productivity, safety, and cost-efficiency. Continued advancements and the ability to meet stringent regulatory requirements will be key factors in realizing their full potential.

Recent Technological development in Vacuum Quick Fitting Market by Key Players

Several key players are making significant strides in the vacuum quick fitting market by incorporating innovative technologies to meet growing demand. Companies like Vuototecnica, Metal Work, AIGNEP, and ITV are introducing next-generation solutions that are enhancing the performance of vacuum quick fittings.

• Vuototecnica has expanded its portfolio with high-performance fittings featuring advanced sealing technology, addressing the growing demand in the medical sector.

• Metal Work is focusing on integrating push-to-connect systems that offer more convenience in high-speed assembly lines.

• AIGNEP has introduced modular vacuum fittings that improve system flexibility and ease of maintenance in food processing.

• ITV has developed vacuum fittings with increased high-pressure resistance, making them suitable for harsher industrial environments.

• Parker Legris and Walther Prazision are enhancing their product lines with improved vacuum sealing technology to improve safety in pharmaceutical applications.

• Albert Fezer Maschinenfabrik continues to advance in the development of eco-friendly materials, aligning with the trend of sustainability in vacuum fitting solutions.

These developments are enhancing product performance, making vacuum quick fittings more adaptable to diverse applications in sectors like food production, medicine, and industrial automation.

Vacuum Quick Fitting Market Driver and Challenges

The vacuum quick fitting market is influenced by a range of drivers and challenges that shape its development.

The factors responsible for driving the global vacuum quick fitting market are:

• Rising automation in manufacturing: Automation in industries like food processing and pharmaceuticals is increasing the demand for efficient, reliable vacuum quick fitting systems.

• Growth in food and pharmaceutical industries: The need for high-precision, sterile environments in these industries is driving the demand for vacuum fittings with better sealing and durability.

• Technological advancements in materials: Innovations in materials used for vacuum fittings, such as eco-friendly polymers, are opening new market opportunities.

• Increasing focus on process efficiency: The trend towards lean manufacturing and process optimization is driving demand for vacuum quick fittings that enable faster, more efficient assembly and production.

Challenges facing the global vacuum quick fitting market are:

• High initial cost of advanced systems: Advanced vacuum quick fittings with features like vacuum sealing and high-pressure resistance come at a higher initial cost, which may deter small-to-medium enterprises.

• Regulatory compliance: Strict regulations in industries like pharmaceuticals and food manufacturing necessitate adherence to safety and quality standards, which can be complex and costly to meet.

• Maintenance and durability issues: Vacuum systems, particularly in high-pressure or sterile environments, require regular maintenance to ensure consistent performance and longevity, posing a challenge for companies that require continuous uptime.

These drivers and challenges are shaping the vacuum quick fitting market, with opportunities in automation, material innovation, and industry growth being balanced by cost considerations, regulatory complexities, and ongoing maintenance needs. The market is poised for growth as new technologies address these issues while meeting the increasing demand for high-performance vacuum systems across industries.

List of Vacuum Quick Fitting Companies

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies vacuum quick fitting companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the vacuum quick fitting companies profiled in this report includes.

• Vuototecnica

• Metal Work

• Aignep

• Itv

• Parker Legris

• Walther Prazision

Vacuum Quick Fitting Market by Technology

• Technology Readiness by Technology Type: The intensity and regulatory compliance in the vacuum quick fitting market vary across different technologies. Quick-release locking systems are widely used for their simplicity and ease of operation, with moderate regulatory oversight mainly focusing on operational safety and system durability. Push-to-connect fittings are gaining popularity due to their ease of use and tool-free installation, with minimal regulatory barriers in most industries. Vacuum sealing technologies are critical in industries requiring sterilization, such as food and pharmaceuticals, and are subject to stringent hygiene and quality regulations to ensure safety and contamination prevention. High-pressure resistance fittings are increasingly used in high-stress environments such as industrial and manufacturing applications and face moderate regulation regarding materials used for pressure tolerance. All these technologies are relatively mature, with push-to-connect and vacuum sealing systems leading in market adoption due to their flexibility, while high-pressure resistance fittings continue to evolve with new material innovations. These technologies are continuously improving to meet the specific needs of different industries while ensuring regulatory compliance.

• Competitive Intensity and Regulatory Compliance: The vacuum quick fitting market is highly competitive with a wide range of players offering different technologies. Key players like Parker Legris, Vuototecnica, and ITV compete based on innovation, cost-efficiency, and ability to meet industry-specific regulatory standards. Technologies such as push-to-connect and vacuum sealing have achieved widespread market adoption due to their simplicity and reliability, making them highly competitive. However, high-pressure resistance and vacuum sealing technologies require specialized materials and manufacturing processes, creating barriers to entry for new competitors. Regulatory compliance remains a key challenge, especially in the food and pharmaceutical sectors, where products must meet rigorous safety, hygiene, and environmental standards. These industries demand high-performance fittings that are durable, reliable, and compliant with local and international regulations.

• Disruption Potential by Technology Type: Vacuum quick fitting technologies are poised to disrupt various sectors with distinct potential for innovation. Push-to-connect systems simplify assembly processes, reducing the need for specialized tools and enabling faster production, making them particularly impactful in automated manufacturing. Quick-release locking systems, by offering easy disconnection, improve maintenance and reduce downtime in production facilities. Vacuum sealing technologies are revolutionizing industries like food processing and pharmaceuticals, where product safety and sterility are paramount, offering significant advancements in contamination control. High-pressure resistance fittings, which allow for safe and durable operation in extreme conditions, are crucial for industries like aerospace and heavy manufacturing. Overall, these technologies, through their ease of use, precision, and ability to improve safety standards, are set to transform manufacturing and industrial sectors, enhancing efficiency, reliability, and overall productivity.

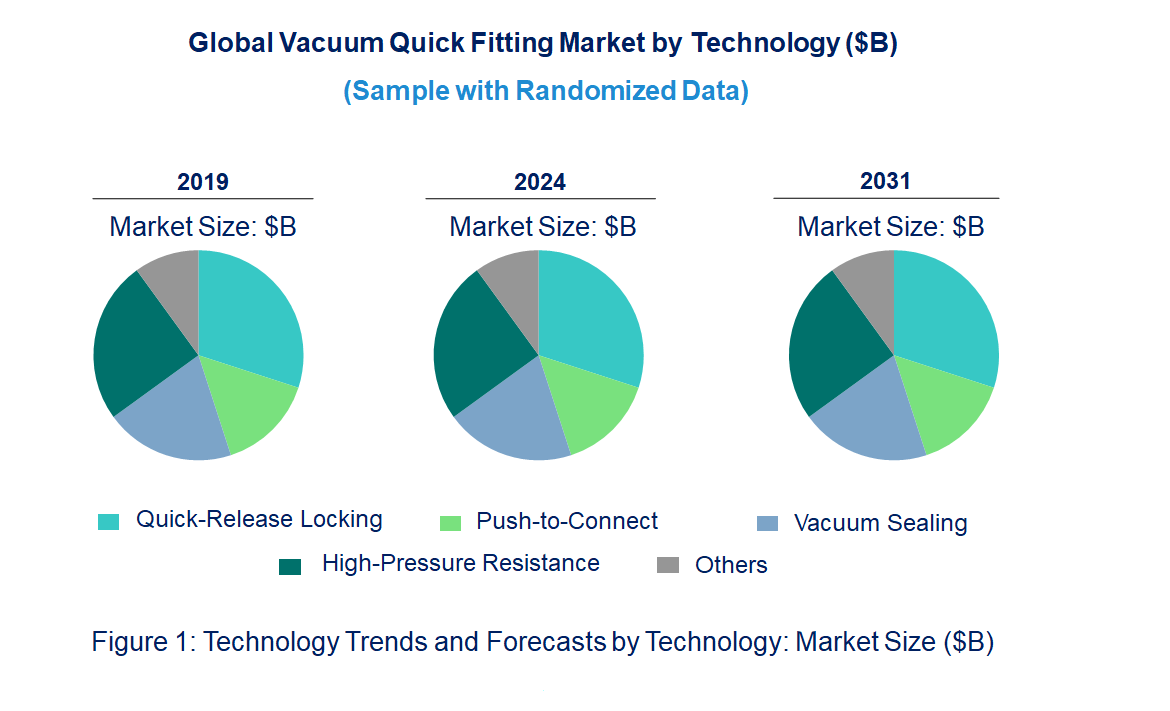

Vacuum Quick Fitting Market Trend and Forecast by Technology [Value from 2019 to 2031]:

• Quick-Release Locking

• Push-to-Connect

• Vacuum Sealing

• High-Pressure Resistance

• Others

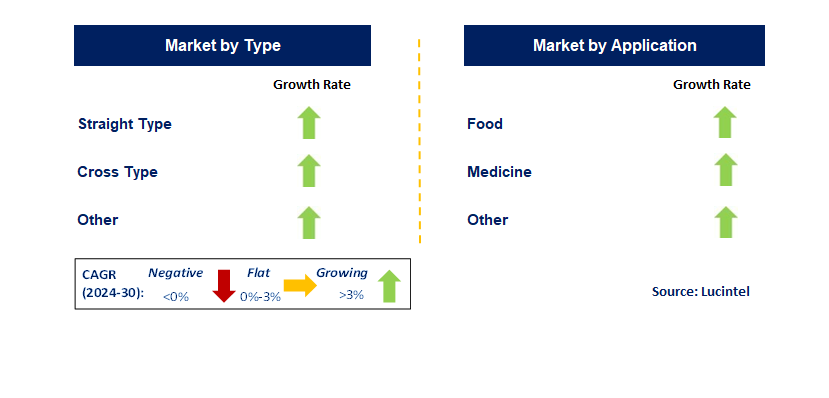

Vacuum Quick Fitting Market Trend and Forecast by Application [Value from 2019 to 2031]:

• Food

• Medicine

• Others

Vacuum Quick Fitting Market by Region [Value from 2019 to 2031]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

• Latest Developments and Innovations in the Vacuum Quick Fitting Technologies

• Companies / Ecosystems

• Strategic Opportunities by Technology Type

Features of the Global Vacuum Quick Fitting Market

Market Size Estimates: Vacuum quick fitting market size estimation in terms of ($B).

Trend and Forecast Analysis: Market trends (2019 to 2024) and forecast (2025 to 2031) by various segments and regions.

Segmentation Analysis: Technology trends in the global vacuum quick fitting market size by various segments, such as application and technology in terms of value and volume shipments.

Regional Analysis: Technology trends in the global vacuum quick fitting market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different applications, technologies, and regions for technology trends in the global vacuum quick fitting market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for technology trends in the global vacuum quick fitting market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

This report answers following 11 key questions

Q.1. What are some of the most promising potential, high-growth opportunities for the technology trends in the global vacuum quick fitting market by technology (quick-release locking, push-to-connect, vacuum sealing, high-pressure resistance, and others), application (food, medicine, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which technology segments will grow at a faster pace and why?

Q.3. Which regions will grow at a faster pace and why?

Q.4. What are the key factors affecting dynamics of different technology? What are the drivers and challenges of these technologies in the global vacuum quick fitting market?

Q.5. What are the business risks and threats to the technology trends in the global vacuum quick fitting market?

Q.6. What are the emerging trends in these technologies in the global vacuum quick fitting market and the reasons behind them?

Q.7. Which technologies have potential of disruption in this market?

Q.8. What are the new developments in the technology trends in the global vacuum quick fitting market? Which companies are leading these developments?

Q.9. Who are the major players in technology trends in the global vacuum quick fitting market? What strategic initiatives are being implemented by key players for business growth?

Q.10. What are strategic growth opportunities in this vacuum quick fitting technology space?

Q.11. What M & A activities did take place in the last five years in technology trends in the global vacuum quick fitting market?