Ultrasonic Bar Inspection System Market Trends and Forecast

The technologies in the ultrasonic bar inspection system market have undergone significant changes in recent years, with a shift from traditional ultrasonic transducer-based systems to more advanced techniques such as phased array ultrasonic, time-of-flight diffraction (TOFD), and pulse echo ultrasonic. These newer technologies have led to improved detection capabilities, greater precision, and enhanced efficiency in inspection processes. For instance, phased array ultrasonic systems provide greater flexibility and the ability to capture detailed imaging of defects, making them ideal for complex geometries and large components. Time-of-flight diffraction (TOFD) systems offer higher sensitivity for detecting cracks and other discontinuities in thick materials, enhancing the overall accuracy of inspections. Additionally, pulse echo ultrasonic techniques are widely used for general thickness measurements and flaw detection, continuing to evolve in terms of speed and accuracy. These shifts reflect the industry’s demand for faster, more reliable, and precise inspection technologies, which are critical in applications like aerospace, steel manufacturing, and automotive production.

Emerging Trends in the Ultrasonic Bar Inspection System Market

The ultrasonic bar inspection system market is witnessing key trends that are reshaping the industry landscape. These trends are driven by the need for greater efficiency, accuracy, and automation in industrial inspections:

• Adoption of Phased Array Ultrasonic Technology: Phased Array Ultrasonic systems are increasingly being adopted for their ability to provide detailed and accurate images, enabling inspectors to identify even the smallest defects in complex materials. This trend is improving the quality and safety of materials in industries like aerospace and automotive.

• Integration of Automation and Robotics: The integration of robotics with ultrasonic inspection systems is becoming a key trend. Automated inspection systems help increase the speed and consistency of inspections, reducing human error and labor costs while improving throughput in industries like steel and automotive.

• Real-Time Data Analysis and Reporting: With the rise of real-time data processing and reporting, ultrasonic bar inspection systems are becoming more efficient in providing immediate feedback on the quality of materials. This trend allows manufacturers to take quick corrective actions, reducing downtime and enhancing production quality.

• Increased Use in Critical Applications: Industries like aerospace and automotive are increasingly using ultrasonic bar inspection systems to ensure the integrity of materials used in critical applications. This trend is driven by the need for superior quality control in safety-critical components like turbine blades and structural parts.

• Technological Integration and Hybrid Systems: Another emerging trend is the development of hybrid systems that combine multiple ultrasonic technologies, such as Phased Array and TOFD, to improve detection capabilities across different material types. This trend offers versatility and improves the overall reliability of inspections.

These trends indicate a shift toward more advanced, automated, and data-driven approaches in the ultrasonic bar inspection systems market, improving both productivity and safety across various industries.

Ultrasonic Bar Inspection System Market : Industry Potential, Technological Development, and Compliance Considerations

The ultrasonic bar inspection system market has seen significant advancements in recent years, driven by the need for enhanced defect detection and quality control in industries like aerospace, automotive, and steel manufacturing. The core technologies in this market include ultrasonic transducers, Phased Array Ultrasonic Testing (PAUT), Time-of-Flight Diffraction (TOFD), and Pulse Echo Ultrasonic Testing, each offering unique advantages in non-destructive testing.

• Technology Potential:

The potential of ultrasonic inspection technology lies in its ability to improve inspection accuracy, speed, and automation. Technologies like PAUT and TOFD enable detailed imaging of material defects such as cracks and voids, significantly improving the quality and safety of critical infrastructure. This is especially crucial in sectors like aerospace, where material integrity is paramount. As these technologies become more sophisticated, they offer even greater potential for real-time, high-resolution defect detection, reducing downtime and improving overall efficiency.

• Degree of Disruption:

Ultrasonic technologies are increasingly disrupting traditional inspection methods by providing faster, more accurate alternatives that allow for deeper analysis with less manual intervention. This shift reduces labor costs, inspection time, and the possibility of human error, making ultrasonic systems a transformative force in industrial inspection.

• Level of Current Technology Maturity:

While PAUT and TOFD technologies are becoming mainstream, some traditional ultrasonic transducer methods are still widely used due to their cost-effectiveness and simplicity. However, the increasing complexity of materials and structures has driven the adoption of more advanced systems, ensuring that these technologies continue to mature.

• Regulatory Compliance:

Regulatory compliance is critical in sectors like aerospace and automotive, where safety standards are strict. Ultrasonic systems must adhere to these standards, requiring manufacturers to integrate the latest technologies while ensuring compliance with industry regulations for quality and safety. This balance of innovation and regulation will shape the future of the ultrasonic bar inspection system market.

Recent Technological development in Ultrasonic Bar Inspection System Market by Key Players

Key players in the ultrasonic bar inspection system market are constantly innovating to meet the increasing demand for higher inspection accuracy and efficiency in industries such as aerospace, automotive, and steel manufacturing.

• Waygate Technologies: Waygate Technologies has significantly advanced its phased array ultrasonic inspection equipment, offering enhanced flexibility and precision for complex and large parts. Their new systems are widely used in critical aerospace and automotive applications, ensuring the integrity of structural materials.

• Evident: Evident has introduced state-of-the-art ultrasonic inspection systems that integrate advanced data analysis tools, enabling real-time monitoring of materials. These systems are especially useful in high-volume steel and automotive manufacturing, where they help identify defects before the final product reaches the market.

• Structural Diagnostics: Structural Diagnostics has been focusing on integrating ultrasonic transducer systems with AI and machine learning for better defect recognition and predictive analysis. This enhances the accuracy and speed of inspections, particularly in challenging applications like pipeline inspection and heavy industrial materials.

• KJTD: KJTD has been a pioneer in introducing pulse echo and phased array systems that support real-time automated inspection in the automotive sector. Their systems have significantly reduced inspection times, allowing manufacturers to improve throughput and reduce operational costs.

• Namicon Testing: Namicon Testing continues to expand its portfolio by offering hybrid ultrasonic systems that combine multiple technologies such as TOFD and phased array for more comprehensive inspection capabilities. These solutions are widely adopted in the aerospace and steel industries for quality control and material integrity assessment.

These developments demonstrate how key players are focusing on improving technology and integrating new solutions to meet the evolving needs of the market.

Ultrasonic Bar Inspection System Market Driver and Challenges

The ultrasonic bar inspection system market is driven by technological advancements and evolving industry requirements. However, there are both opportunities and challenges that shape its growth.

The factors responsible for driving the global ultrasonic bar inspection system market are:

• Demand for High Precision and Quality Control: The need for precise, real-time inspection in industries like aerospace and automotive is pushing the adoption of ultrasonic systems. This demand for high-quality materials ensures safety and reliability, particularly in critical applications like turbine blades and structural components.

• Automation and Industry 4.0 Integration: The growing trend of automation in manufacturing, as part of Industry 4.0, is driving the development and adoption of automated ultrasonic inspection systems. These systems offer greater efficiency, reduce labor costs, and ensure consistent, high-quality inspections.

• Increasing Use of Advanced Materials: The adoption of advanced materials in aerospace and automotive industries, which require specialized inspection techniques, is driving the need for more sophisticated ultrasonic bar inspection systems capable of detecting minute defects in complex materials.

• Real-Time Data Processing: The rise of real-time data analysis and predictive analytics in ultrasonic inspection systems is enabling quicker decision-making, reducing downtime, and enhancing production efficiency.

Challenges facing the global ultrasonic bar inspection system market are:

• High Initial Investment: The adoption of advanced ultrasonic inspection systems requires high initial investment, which may deter smaller manufacturers or those with limited capital from making the shift.

• Training and Skill Gap: The complexity of modern ultrasonic systems and the integration of advanced technologies such as AI and robotics require specialized training for operators. The skill gap in these areas can delay the adoption and efficient use of the technology.

• Regulatory Compliance: Stringent regulatory requirements for industries like aerospace and automotive place pressure on ultrasonic inspection system providers to ensure their products meet safety standards and certification processes, which can slow down the development and market introduction of new systems.

In conclusion, while the growth drivers indicate a strong future for the Ultrasonic Bar Inspection System Market, challenges related to cost, training, and regulatory compliance need to be addressed for broader adoption and faster industry transformation.

List of Ultrasonic Bar Inspection System Companies

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies ultrasonic bar inspection system companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the ultrasonic bar inspection system companies profiled in this report includes.

• Waygate Technologies

• Evident

• Structural Diagnostics

• Kjtd

• Namicon Testing

Ultrasonic Bar Inspection System Market by Technology

• Technology Readiness: PAUT and TOFD are mature, widely used in industries needing high precision, such as aerospace and energy. Pulse Echo Ultrasonic is still widely used due to its simplicity, while ultrasonic transducers remain fundamental for basic inspections. Regulatory compliance and technological advancement are key factors driving adoption, with innovations enhancing efficiency and accuracy in inspection practices.

• Competitive Intensity and Regulatory Compliance: The ultrasonic bar inspection system market is competitive, with major players like Waygate Technologies and Evident pushing for advanced inspection systems. PAUT and TOFD lead due to their precision, but traditional technologies like Ultrasonic Transducers and Pulse Echo remain popular due to their lower cost and ease of use. Strict regulatory compliance, especially in aerospace and automotive, ensures that all technologies meet industry standards for safety and quality.

• Disruption Potential: Technologies like phased array ultrasonic (PAUT) and time-of-flight diffraction (TOFD) are disrupting the ultrasonic bar inspection market by providing higher accuracy, better defect detection, and real-time imaging compared to traditional methods like ultrasonic transducers and pulse echo ultrasonic. PAUT and TOFD enable more detailed inspections, especially in complex materials, and are replacing older systems in critical industries like aerospace and steel.

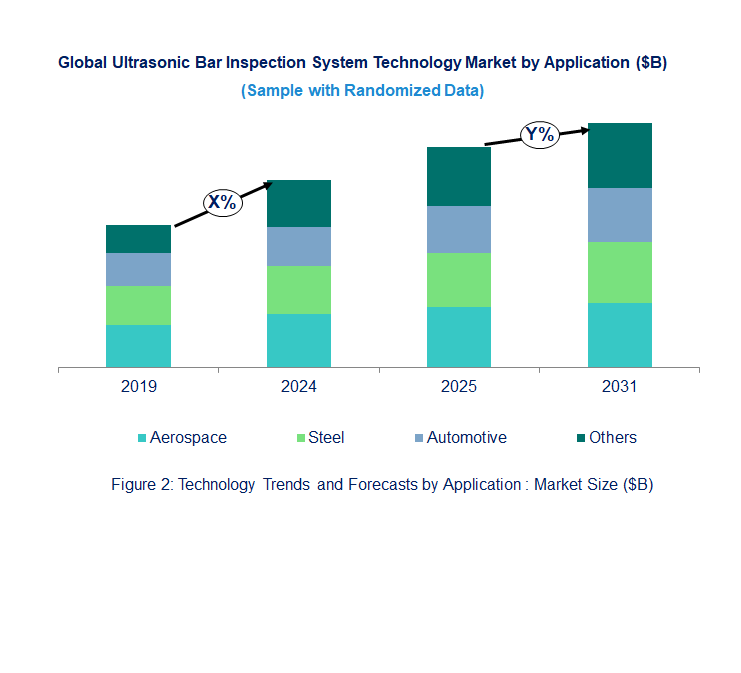

Ultrasonic Bar Inspection System Market Trend and Forecast by Technology [Value from 2019 to 2031]:

• Ultrasonic Transducer

• Phased Array Ultrasonic

• Time-of-Flight Diffraction (TOFD)

• Pulse Echo Ultrasonic

• Others

Ultrasonic Bar Inspection System Market Trend and Forecast by Application [Value from 2019 to 2031]:

• Aerospace

• Steel

• Automotive

• Others

Ultrasonic Bar Inspection System Market by Region [Value from 2019 to 2031]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

• Latest Developments and Innovations in the Ultrasonic Bar Inspection System Technologies

• Companies / Ecosystems

• Strategic Opportunities by Technology Type

Features of the Global Ultrasonic Bar Inspection System Market

Market Size Estimates: Ultrasonic bar inspection system market size estimation in terms of ($B).

Trend and Forecast Analysis: Market trends (2019 to 2024) and forecast (2025 to 2031) by various segments and regions.

Segmentation Analysis: Technology trends in the global ultrasonic bar inspection system market size by various segments, such as application and technology in terms of value and volume shipments.

Regional Analysis: Technology trends in the global ultrasonic bar inspection system market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different applications, technologies, and regions for technology trends in the global ultrasonic bar inspection system market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for technology trends in the global ultrasonic bar inspection system market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

This report answers following 11 key questions

Q.1. What are some of the most promising potential, high-growth opportunities for the technology trends in the global ultrasonic bar inspection system market by technology (ultrasonic transducer, phased array ultrasonic, time-of-flight diffraction (tofd), pulse echo ultrasonic, and others), application (aerospace, steel, automotive, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which technology segments will grow at a faster pace and why?

Q.3. Which regions will grow at a faster pace and why?

Q.4. What are the key factors affecting dynamics of different technology? What are the drivers and challenges of these technologies in the global ultrasonic bar inspection system market?

Q.5. What are the business risks and threats to the technology trends in the global ultrasonic bar inspection system market?

Q.6. What are the emerging trends in these technologies in the global ultrasonic bar inspection system market and the reasons behind them?

Q.7. Which technologies have potential of disruption in this market?

Q.8. What are the new developments in the technology trends in the global ultrasonic bar inspection system market? Which companies are leading these developments?

Q.9. Who are the major players in technology trends in the global ultrasonic bar inspection system market? What strategic initiatives are being implemented by key players for business growth?

Q.10. What are strategic growth opportunities in this ultrasonic bar inspection system technology space?

Q.11. What M & A activities did take place in the last five years in technology trends in the global ultrasonic bar inspection system market?