Stem Cell Manufacturing Market Trends and Forecast

Technologies in the stem cell manufacturing market have advanced over time, shifting from manual cell production techniques to the automation of cell production systems, improving efficiency and scalability. In addition, there has been a shift from traditional cryopreservation methods to advanced cryopreservation technologies such as controlled-rate freezing and vitrification, which improve cell viability and storage life expectancy. Another significant trend is the transition from basic cell expansion technologies to high-level bioreactor-based expansion systems, which provide higher yields and more reproducible cell cultures. Additionally, there is a trend away from standard cell acquisition methods and toward novel stem cell sourcing technologies like iPSCs, which facilitate broader applications and reduce ethical concerns. Furthermore, the development of automated sub-culture systems has improved the consistency and reproducibility of cell lines, making the shift from basic sub-culture techniques possible. These technological shifts are driving improvements in the efficiency, cost-effectiveness, and scalability of stem cell production processes, supporting the growing demand in pharmaceutical, biotechnology, and research applications.

Emerging Trends in the Stem Cell Manufacturing Market

The stem cell manufacturing market is experiencing significant advancements driven by new technologies and increased demand across pharmaceutical, biotechnology, and research sectors. As the potential of stem cell therapies continues to expand, the industry is transforming manufacturing processes. These advancements are improving efficiency, scalability, and cost-effectiveness, while also addressing ethical concerns and regulatory challenges. Below are five key emerging trends shaping the future of the stem cell manufacturing market.

• Shift from Manual to Automated Production Systems: Automation in cell production is becoming a key trend in stem cell manufacturing. Automation improves efficiency, reduces human error, and enables scalability. Automated systems allow for more consistent and reproducible production of stem cells, which is essential for clinical applications and large-scale manufacturing.

• Advancements in Cryopreservation Technologies: Cryopreservation techniques are evolving from traditional methods to advanced technologies, such as controlled-rate freezing and vitrification. These methods ensure higher cell viability during storage, which is crucial for long-term storage and transport of stem cells.

• Development of Bioreactor-based Expansion Technologies: Bioreactor-based systems are becoming more common for stem cell expansion. These systems provide a controlled environment for growing large quantities of stem cells, offering better yields and greater consistency compared to traditional methods.

• Adoption of Induced Pluripotent Stem Cells (iPSCs): iPSCs, derived from adult cells, are gaining popularity over embryonic stem cells due to fewer ethical concerns. iPSCs offer a renewable and versatile source of stem cells, making them ideal for a wide range of therapeutic applications.

• Integration of Smart Technologies in Manufacturing: The integration of IoT and AI technologies into stem cell manufacturing systems is improving process monitoring and control. These technologies allow for real-time tracking of cell culture conditions, ensuring that cells are maintained under optimal conditions for growth and differentiation.

These emerging trends are transforming the stem cell manufacturing market by driving innovation in production techniques, increasing efficiency, and addressing ethical and regulatory challenges. Automation, advanced cryopreservation, bioreactor expansion systems, iPSCs, and the integration of smart technologies are reshaping the industry to meet the growing demand for stem cell-based therapies. As these technologies continue to evolve, they will play a critical role in making stem cell therapies more accessible, cost-effective, and scalable, accelerating the path to clinical applications.

Stem Cell Manufacturing Market : Industry Potential, Technological Development, and Compliance Considerations

The stem cell manufacturing market is driven by several key technologies that are reshaping the way stem cells are produced, preserved, and expanded for therapeutic applications. These technologies offer significant potential for disruption, as they aim to improve efficiency, scalability, and cost-effectiveness while addressing ethical and regulatory challenges.

• Potential in Technology:

Advancements in automation, bioreactor-based expansion, cryopreservation technologies, and induced pluripotent stem cells (iPSCs) have the potential to greatly enhance the scalability of stem cell production, making it more viable for clinical use. The integration of IoT and AI technologies further strengthens real-time monitoring and predictive maintenance, ensuring high-quality and consistent production of stem cells.

• Degree of Disruption:

These technologies are disruptive in their ability to streamline complex manufacturing processes, reduce labor costs, and improve cell viability for long-term storage and therapeutic use. Bioreactors, for example, significantly improve scalability, while iPSCs provide an ethically acceptable alternative to embryonic stem cells.

• Current Level of Technology Maturity:

While technologies such as cryopreservation, automation, and iPSCs have reached a high level of maturity, the use of AI, IoT, and bioreactor-based systems for large-scale stem cell production is still evolving, though rapidly advancing.

• Regulatory Compliance:

Regulatory frameworks for stem cell manufacturing are stringent due to ethical concerns. Technologies like iPSCs face less regulatory scrutiny compared to embryonic stem cells, but all technologies must comply with both local and international safety and efficacy standards.

Recent Technological development in Stem Cell Manufacturing Market by Key Players

The stem cell manufacturing market is evolving rapidly with advancements from leading players such as Advanced Cell, STEMCELL Technologies, Cellular Engineering Technologies, CellGenix, and PromoCell. These companies are at the forefront of innovations in stem cell production, cryopreservation, expansion technologies, and manufacturing processes, driving growth in the biotechnology and pharmaceutical industries. The development of new stem cell technologies and improved manufacturing techniques have significantly enhanced scalability, reproducibility, and cost-effectiveness, allowing these companies to meet the growing demand for stem cell-based therapies. Below are the key recent developments from these companies:

• Advanced Cell: Advanced Cell has made significant strides in the development of automated stem cell production systems. Their innovative bioreactor-based technologies allow for the mass production of stem cells with increased efficiency and scalability. The integration of automation into the production process not only reduces labor costs but also ensures a more consistent and reproducible output, addressing the high demand for clinical-grade stem cells.

• STEMCELL Technologies: STEMCELL Technologies has focused on expanding its portfolio of cell culture media and reagents tailored for stem cell research and therapeutic applications. The company has launched new media formulations that support the efficient culture and expansion of induced pluripotent stem cells (iPSCs) and mesenchymal stem cells (MSCs). These advancements improve cell viability and differentiation capabilities, making them more suitable for clinical and therapeutic use.

• Cellular Engineering Technologies: Cellular Engineering Technologies has pioneered bioreactor-based expansion systems that are scalable and highly efficient. These bioreactors provide an optimal environment for stem cell growth, allowing for increased yields and reproducibility in large-scale manufacturing. Their systems are helping bridge the gap between laboratory-scale stem cell production and clinical-grade manufacturing, ensuring the supply of high-quality stem cells for regenerative medicine.

• CellGenix: CellGenix has focused on developing high-quality, GMP-grade media for the culture and expansion of stem cells. The company recently introduced customized media solutions for specific types of stem cells, improving their ability to support large-scale production for clinical trials and therapies. Their media formulations are critical in ensuring the consistency and reliability of stem cell cultures, which are essential for therapeutic applications.

• PromoCell: PromoCell has made notable advances in cell banking and cryopreservation technologies. They offer customized cryopreservation services for stem cells, ensuring that cell lines are preserved under optimal conditions for long-term storage and later use. PromoCellÄX%$%Xs solutions support the efficient storage and transportation of stem cells globally, allowing for better access to therapeutic applications and improving supply chain management for clinical trials.

The ongoing developments in stem cell manufacturing by key players such as Advanced Cell, STEMCELL Technologies, Cellular Engineering Technologies, CellGenix, and PromoCell are significantly improving the scalability, quality, and cost-effectiveness of stem cell production. These companies are shaping the future of regenerative medicine by advancing technologies that address key challenges in production, storage, and delivery of stem cells for therapeutic use. As these technologies continue to evolve, the industry will see an increase in clinical-grade stem cell applications, enhancing the accessibility and effectiveness of stem cell-based therapies.

Stem Cell Manufacturing Market Driver and Challenges

The stem cell manufacturing market is rapidly expanding, driven by advances in technology and the increasing demand for stem cell-based therapies across regenerative medicine, drug development, and personalized treatments. However, despite its growth potential, the industry faces several challenges including high production costs, regulatory hurdles, and the complexity of large-scale manufacturing. Below, we explore the key drivers and challenges influencing this market.

The factors responsible for driving the stem cell manufacturing market include:

• Advancements in Automation and Robotics: Automation is transforming stem cell manufacturing by improving scalability, efficiency, and reducing human error. Automated systems streamline complex processes like cell production, expansion, and sub-culturing, enabling high-quality, large-scale production. This drives down labor costs and accelerates the commercial production of stem cells for therapeutic use.

• Technological Advancements in Cryopreservation: Innovations in cryopreservation technologies, such as vitrification and controlled-rate freezing, enhance the storage and transport of stem cells while preserving their viability. This improves the global accessibility of stem cells, especially in clinical trials and regenerative medicine, increasing the potential for their use in therapeutic applications worldwide.

• Ethical Acceptance of Induced Pluripotent Stem Cells (iPSCs): The growing use of iPSCs, derived from adult cells, addresses ethical concerns surrounding embryonic stem cells. iPSCs provide a renewable and versatile source of stem cells, enabling the development of personalized therapies with fewer regulatory barriers, further driving their adoption in clinical and research applications.

• Integration of Smart Technologies (IoT & AI): The integration of Internet of Things (IoT) and Artificial Intelligence (AI) technologies in stem cell manufacturing enhances real-time monitoring, predictive maintenance, and process optimization. These smart systems ensure higher precision in cell culture conditions, improve process efficiency, and reduce errors, supporting large-scale and consistent production.

• Increasing Demand for Regenerative Medicine and Personalized Therapies: As the demand for regenerative medicine and personalized treatments rises, the need for scalable and reliable stem cell manufacturing technologies intensifies. These therapies hold great promise for conditions such as cancer, cardiovascular diseases, and neurological disorders, further boosting the stem cell manufacturing market’s growth potential.

Challenges in the stem cell manufacturing market are:

• High Production Costs: Stem cell manufacturing remains costly due to the complexity of production processes, high-quality raw materials, and the need for advanced equipment. These high costs can limit the affordability and accessibility of stem cell-based therapies, particularly in emerging markets and for patients who may not have access to personalized treatments.

• Regulatory and Ethical Challenges: Despite the shift towards iPSCs, the stem cell manufacturing market continues to face regulatory scrutiny, particularly in the use of embryonic stem cells and gene editing technologies. Navigating complex regulatory requirements in different countries and ensuring compliance with safety and efficacy standards can slow market growth and product approval.

• Scalability and Reproducibility: Scaling up stem cell production while maintaining consistency, purity, and efficacy is challenging. Variability in cell lines, culture conditions, and bioreactor performance can affect the quality of the final product, making large-scale manufacturing difficult. Achieving reproducibility across different batches and manufacturers remains a significant hurdle.

The Stem Cell Manufacturing Market is growing rapidly, driven by technological advancements, ethical acceptance of iPSCs, and increasing demand for regenerative therapies. However, challenges such as high production costs, regulatory hurdles, scalability issues, and a shortage of skilled labor remain barriers to broader adoption. Addressing these challenges while leveraging opportunities like automation, smart technologies, and cryopreservation innovations will be key to unlocking the market’s full potential. As these growth drivers continue to evolve, the stem cell manufacturing market will likely expand to meet the growing demand for cutting-edge therapies and personalized medicine.

List of Stem Cell Manufacturing Companies

Companies in the market compete based on product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies stem cell manufacturing companies cater to increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the stem cell manufacturing companies profiled in this report include.

• Advanced Cell

• Stemcell

• Cellular Engineering

• Cellgenix

• Promocell

Stem Cell Manufacturing Market by Technology

• Technology Readiness by Technology Type: The technology readiness in the stem cell manufacturing market varies across different technologies. Cell acquisition technologies, such as iPSCs, are well-established and widely used, providing a robust and ethically acceptable source of stem cells. Cell production technologies are rapidly evolving, with automation now becoming the standard in large-scale manufacturing, improving efficiency and scalability. Cryopreservation technologies, including vitrification and controlled-rate freezing, have reached a high level of maturity, offering reliable solutions for the long-term storage and transportation of stem cells. Expansion technologies, particularly bioreactors, are still developing, but their ability to provide a controlled, scalable environment for cell growth is highly promising, with several companies offering advanced bioreactor systems. Sub-culture technologies, especially automated systems, are growing in adoption, improving reproducibility and consistency in stem cell lines. Across these technologies, regulatory compliance is a critical factor, as companies must meet GMP and FDA guidelines. These technologies are poised to expand their applications in clinical settings, enhancing the availability and scalability of stem cell therapies.

• Competitive Intensity and Regulatory Compliance: The competitive intensity in the stem cell manufacturing market is high, with companies like STEMCELL Technologies, Advanced Cell, and CellGenix driving innovations in multiple technologies. As the market grows, companies are racing to develop more efficient and scalable systems, particularly for cell production and bioreactor-based expansion. Regulatory compliance is stringent, as stem cell therapies are subject to rigorous safety and efficacy standards, especially in the cryopreservation and cell acquisition processes. Technologies like iPSCs face fewer ethical challenges but still require adherence to regulatory guidelines. Companies must meet international standards such as GMP (Good Manufacturing Practice) and FDA regulations to ensure the safety of stem cell products. The evolving regulatory environment and competitive pressures push companies to innovate while ensuring patient safety and ethical practices, maintaining a balance between compliance and market demands.

• Disruption Potential of Different Technologies: The disruption potential in stem cell manufacturing technologies is significant, with each technology driving innovation and improving scalability. Cell acquisition technologies, particularly induced pluripotent stem cells (iPSCs), offer a renewable and ethically acceptable source of stem cells, disrupting traditional methods of cell sourcing. Cell production has shifted from manual to automated systems, enhancing efficiency and reproducibility. Cryopreservation techniques, such as vitrification and controlled-rate freezing, improve stem cell viability and long-term storage, disrupting traditional freezing methods. Expansion technologies, such as bioreactors, allow large-scale cell growth with better consistency, revolutionizing how stem cells are cultivated for clinical use. Sub-culture technologies, especially automated systems, offer increased reproducibility and reduced human error, disrupting conventional manual sub-culturing practices. Collectively, these technologies are creating more efficient, scalable, and cost-effective manufacturing systems, accelerating the transition from research to clinical applications.

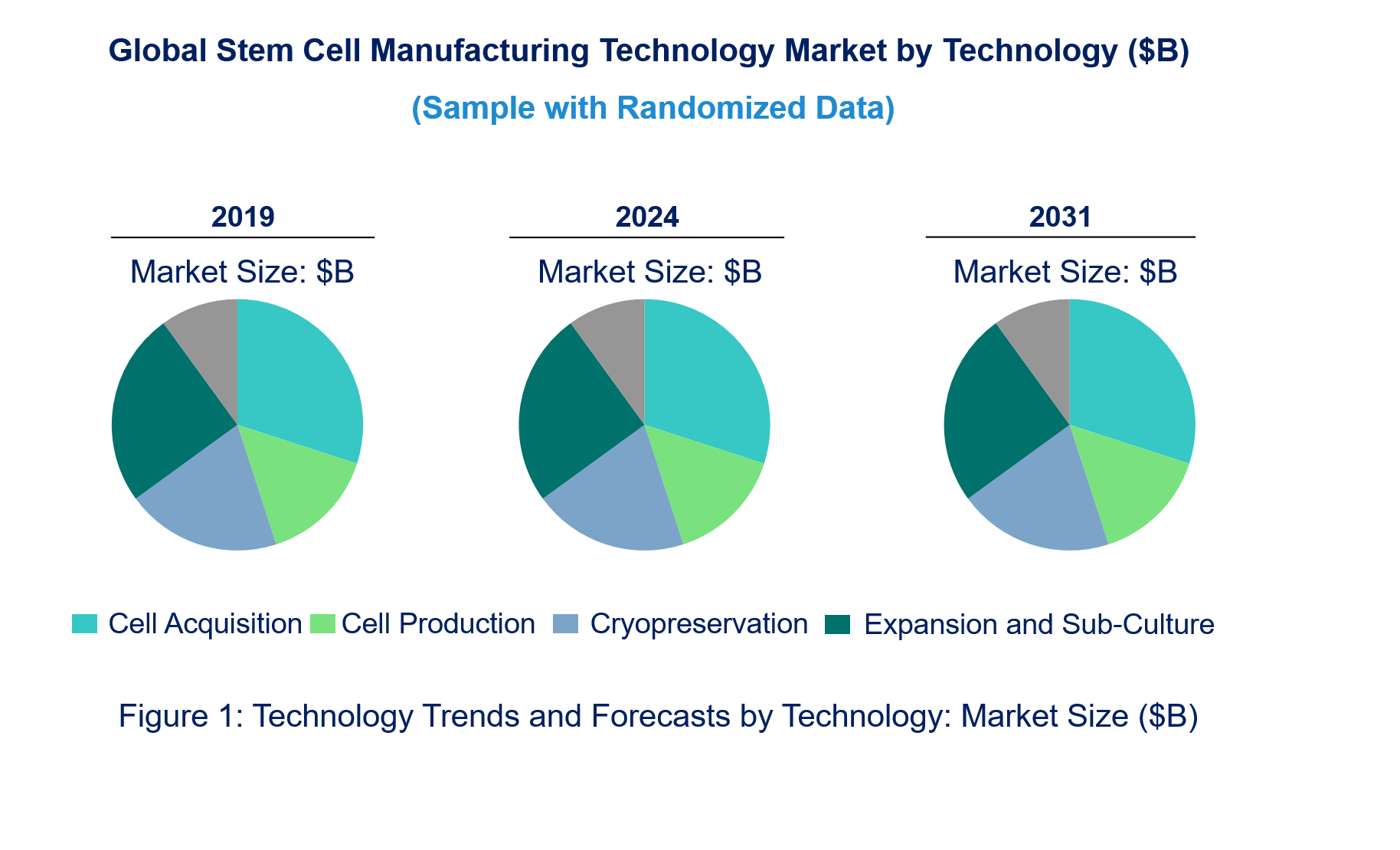

Stem Cell Manufacturing Market Trend and Forecast by Technology [Value from 2019 to 2031]:

• Cell Acquisition

• Cell Production

• Cryopreservation

• Expansion and Sub-Culture

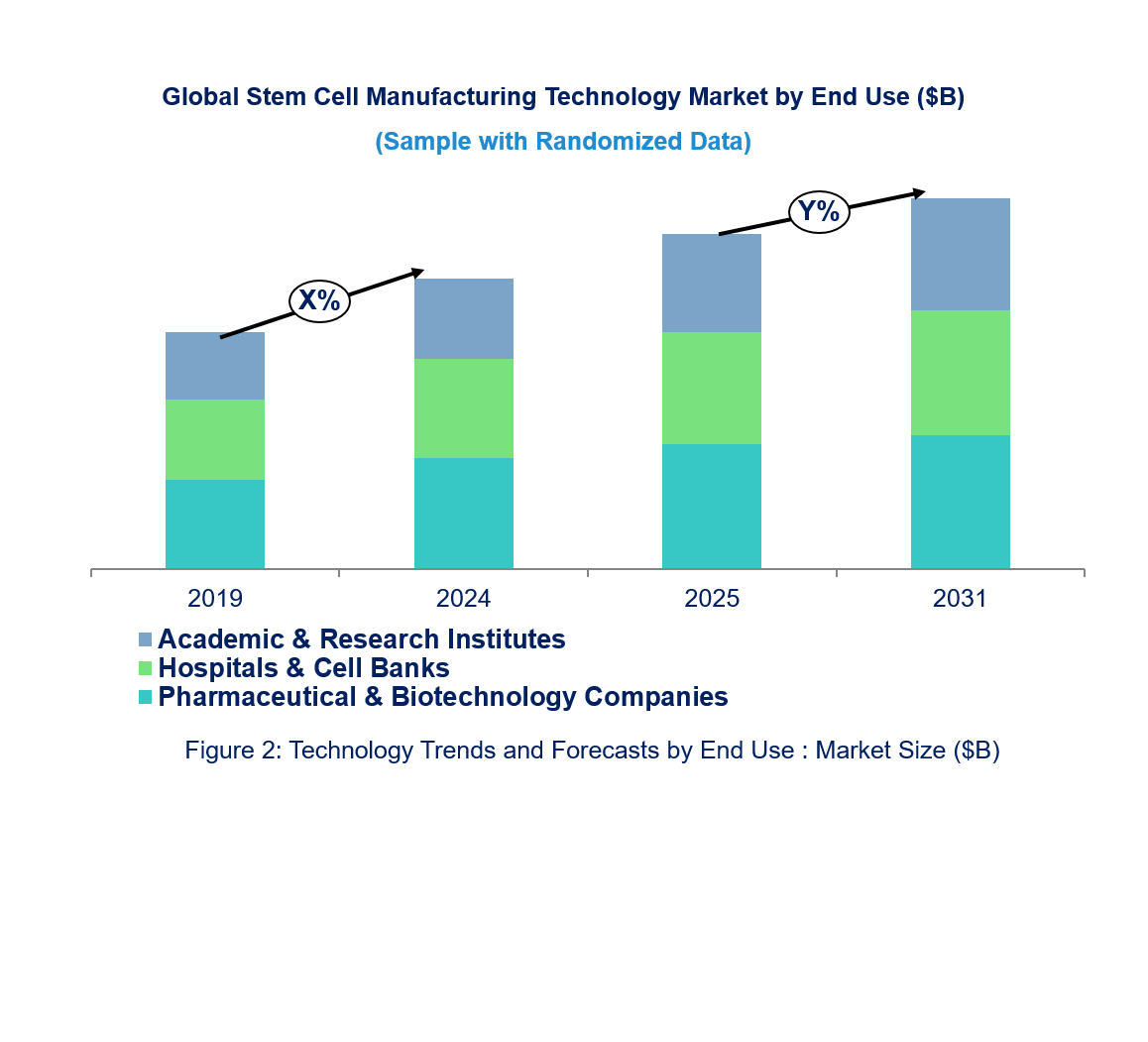

Stem Cell Manufacturing Market Trend and Forecast by End Use Industry [Value from 2019 to 2031]:

• Pharmaceutical & Biotechnology Companies

• Hospitals & Cell Banks

• Academic & Research Institutes

Stem Cell Manufacturing Market by Region [Value from 2019 to 2031]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

• Latest Developments and Innovations in the Stem Cell Manufacturing Technologies

• Companies / Ecosystems

• Strategic Opportunities by Technology Type

Features of the Global Stem Cell Manufacturing Market

Market Size Estimates: Stem cell manufacturing market size estimation in terms of ($B).

Trend and Forecast Analysis: Market trends (2019 to 2024) and forecast (2025 to 2031) by various segments and regions.

Segmentation Analysis: Technology trends in the global stem cell manufacturing market size by various segments, such as end use industry and technology in terms of value and volume shipments.

Regional Analysis: Technology trends in the global stem cell manufacturing market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different end use industries, technologies, and regions for technology trends in the global stem cell manufacturing market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for technology trends in the global stem cell manufacturing market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

This report answers following 11 key questions

Q.1. What are some of the most promising potential, high-growth opportunities for the technology trends in the global stem cell manufacturing market by technology (cell acquisition, cell production, cryopreservation, and expansion and sub-culture), end use industry (pharmaceutical & biotechnology companies, hospitals & cell banks, and academic & research institutes), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which technology segments will grow at a faster pace and why?

Q.3. Which regions will grow at a faster pace and why?

Q.4. What are the key factors affecting dynamics of different technologies? What are the drivers and challenges of these technologies in the global stem cell manufacturing market?

Q.5. What are the business risks and threats to the technology trends in the global stem cell manufacturing market?

Q.6. What are the emerging trends in these technologies in the global stem cell manufacturing market and the reasons behind them?

Q.7. Which technologies have potential of disruption in this market?

Q.8. What are the new developments in the technology trends in the global stem cell manufacturing market? Which companies are leading these developments?

Q.9. Who are the major players in technology trends in the global stem cell manufacturing market? What strategic initiatives are being implemented by key players for business growth?

Q.10. What are strategic growth opportunities in this stem cell manufacturing technology space?

Q.11. What M & A activities did take place in the last five years in technology trends in the global stem cell manufacturing market?