Robotic Screwdriving Market Trends and Forecast

The robotic screwdriving market has undergone significant changes in recent years, with a shift from manual or semi-automated screwdriving systems to fully autonomous, intelligent systems. This includes advancements in technologies like vision-based screw detection evolving into AI-powered vision systems, enhancing accuracy and speed. Torque control has moved from basic mechanical systems to advanced electronic torque systems, offering more precision and flexibility. Additionally, robotic arm integration has shifted from isolated systems to more integrated and collaborative robotic solutions with enhanced flexibility. Autonomous screwfeeding has advanced from simple vibratory feeders to more sophisticated smart autonomous systems, enabling higher levels of automation. These technology shifts are improving efficiency, precision, and flexibility, driving increased adoption in industries like electronics manufacturing, industrial assembly, and construction.

Emerging Trends in the Robotic Screwdriving Market

The robotic screwdriving market is evolving rapidly, with key emerging trends reshaping industries such as electronics, construction, and industrial assembly. These trends emphasize automation, efficiency, and precision.

• AI and Vision-based Screw Detection: AI-powered vision systems have revolutionized screw detection, improving alignment and minimizing errors in screwdriving operations, especially in electronics manufacturing where precision is critical.

• Collaborative Robotics Integration: Robotic arms are increasingly integrated into human work environments, allowing for more flexible and efficient workflows. These collaborative robots work safely alongside humans, increasing productivity in various applications.

• Autonomous Screwfeeding: Automated screw feeding systems are advancing, with systems now able to autonomously detect, organize, and deliver screws, reducing human intervention and boosting productivity, particularly in high-volume production.

• Torque Control Systems with Enhanced Precision: Electronic torque control is improving in accuracy and flexibility, enabling robots to handle delicate tasks in sectors like automotive and electronics manufacturing, where consistent torque is essential.

• Industry 4.0 Integration: The adoption of Industry 4.0 technologies, including IoT and real-time data analytics, is increasing. This trend allows robotic screwdrivers to communicate and optimize operations in real time, leading to more efficient and predictable processes.

These trends are driving innovation and increased adoption of robotic screwdriving systems across various industries, offering solutions for both high-volume and customized production environments.

Robotic Screwdriving Market : Industry Potential, Technological Development, and Compliance Considerations

• Technology Potential:

The robotic screwdriving market is positioned for substantial growth due to innovations in automation, AI, and robotics. These technologies have the potential to significantly enhance efficiency, accuracy, and consistency in assembly lines, particularly in industries like electronics manufacturing, automotive, and construction. Vision-based screw detection, autonomous screwfeeding, and torque control systems are improving the speed and reliability of screwdriving tasks, enabling robots to handle complex, high-precision operations. This offers increased customization, reduced manual labor, and improved production rates.

• Degree of Disruption:

Robotic screwdriving systems are disrupting traditional manual assembly methods. By automating repetitive screwdriving tasks, these systems reduce human error, minimize cycle times, and improve overall production efficiency. They are transforming industries by enabling faster, safer, and more accurate assembly operations. The automation of screwdriving in high-volume environments reduces dependency on skilled labor, offering a competitive edge for manufacturers.

• Level of Current Technology Maturity:

While robotic screwdriving technologies are maturing, there is still room for further innovation, particularly in AI and machine learning-driven vision systems for screw detection and torque control. These systems are reliable in industrial settings but continue to evolve for greater flexibility and precision.

• Regulatory Compliance:

Robotic screwdrivers must adhere to safety and quality regulations, particularly in industries like aerospace, automotive, and electronics, where precision and reliability are critical. Regulatory compliance is becoming better integrated into the development of robotic systems, ensuring safe and effective automation for these sectors.

In conclusion, robotic screwdriving technologies offer immense potential for disrupting manufacturing processes. As the technology matures and meets regulatory standards, it will increasingly shape the future of automation in various industries.

Recent Technological development in Robotic Screwdriving Market by Key Players

In recent years, several players in the Robotic Screwdriving Market have made significant advancements to enhance the performance and capabilities of robotic screwdriving systems.

• OnRobot has developed collaborative robotic tools that integrate with existing robot arms, offering modular screwdriving solutions suitable for diverse applications like electronics and automotive manufacturing. Their systems focus on precision and ease of integration, which have gained popularity in assembly lines.

• Janome Industrial Equipment has introduced high-precision screwdriving systems with enhanced torque control and automation features, supporting industries like automotive and industrial assembly. Their systems focus on precision and versatility, helping companies reduce assembly time and improve quality.

• Mountz Torque offers advanced electronic torque tools, providing manufacturers with flexible, accurate, and reliable screwdriving solutions. Their integration of wireless torque measurement and analysis systems enhances process control and productivity in various sectors.

• Optimo Robotics focuses on AI-powered vision systems that help with screw detection and alignment, improving the overall efficiency of automated screwdriving processes in electronics manufacturing and other precision industries.

• Dixon Automatic Tool provides solutions for high-speed screwdriving and assembly lines, introducing automated screw feeders and customized robotic arms that improve operational efficiency in heavy-duty industries like construction and aerospace.

These developments are helping robotic screwdriving systems become more flexible, precise, and adaptable to different applications. Companies that integrate these advanced technologies will continue to drive market growth by addressing the rising demand for automation and precision in manufacturing.

Robotic Screwdriving Market Driver and Challenges

The robotic screwdriving market is being influenced by a range of drivers and challenges that impact its adoption and growth.

The factors responsible for driving the global robotic screwdriving market are:

• Increasing demand for automation: As industries strive to improve productivity and reduce labor costs, the demand for automated screwdriving systems is increasing. Robotics offer efficiency and consistency, leading to reduced cycle times and improved quality.

• Advancements in AI and machine learning: The integration of AI into robotic screwdriving systems enables better screw detection, alignment, and precision, reducing human error and increasing operational efficiency.

• Rising labor costs: As labor costs continue to rise, industries are turning to robotic systems as a cost-effective solution to replace manual labor in repetitive and time-consuming tasks, especially in electronics manufacturing and automotive assembly.

• Customization and flexibility: With the increasing demand for customized products, robotic screwdriving systems are being adapted to handle varying screw types and sizes, increasing their versatility across different industries.

Challenges facing the global robotic screwdriving market are:

• High initial investment: The cost of implementing robotic screwdriving systems, including hardware, software, and integration into existing production lines, can be a significant barrier for smaller manufacturers.

• Integration with legacy systems: Many companies face challenges in integrating new robotic screwdriving technologies with older systems, requiring time, resources, and expertise to make these systems work together.

• Skilled labor shortage: While automation reduces the need for manual labor, there is still a demand for skilled workers to manage and maintain these advanced robotic systems. The shortage of skilled technicians can slow adoption and limit growth.

The robotic screwdriving market is evolving rapidly, driven by technological advancements such as AI, automation, and collaborative robotics. While opportunities for growth are significant, challenges such as high initial costs, system integration, and skilled labor shortages remain. Overcoming these hurdles will allow companies to take full advantage of the benefits that robotic screwdriving solutions offer in improving efficiency, precision, and flexibility across diverse industries.

List of Robotic Screwdriving Companies

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies robotic screwdriving companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the robotic screwdriving companies profiled in this report includes.

• Onrobot

• Janome Industrial Equipment

• Mountz Torque

• Optimo Robotics

• Dixon Automatic Tool

Robotic Screwdriving Market by Technology

• Technology Readiness by Technology Type in Robotic Screwdriving Market: The robotic screwdriving market has seen varying levels of readiness among technologies like vision-based screw detection, torque control, robotic arm integration, and autonomous screwfeeding. Vision-based screw detection is at a high level of readiness, with advanced AI-powered systems offering precise screw alignment and detection in real-time, especially in electronics and automotive manufacturing. Torque control systems are also well-developed, offering precise control in critical assembly tasks, and are widely used in high-precision industries like aerospace. Robotic arm integration is mature, with several companies offering flexible, collaborative robotic arms that can work alongside humans in assembly lines. Autonomous screwfeeding is rapidly advancing, with automated feeders increasingly able to detect, deliver, and handle screws without human intervention, primarily in mass production environments. While all these technologies are relatively mature, ongoing innovation is needed for further refinement in terms of cost efficiency, ease of integration, and adaptability across diverse applications. Regulatory compliance remains a key factor, as these technologies must adhere to strict standards in sectors like aerospace and automotive.

• Competitive Intensity and Regulatory Compliance of Technologies in Robotic Screwdriving Market: The robotic screwdriving market is highly competitive due to the rapid pace of technological advancement in vision-based screw detection, torque control, robotic arm integration, and autonomous screwfeeding. Companies are continuously innovating to provide faster, more efficient, and customizable solutions to meet the growing demand for automation. The competitive intensity is high, especially as robotics and AI technologies continue to improve. However, regulatory compliance is a critical factor that influences the competitiveness of these technologies, particularly in industries like aerospace, automotive, and electronics, where safety, precision, and quality standards are essential. Technologies such as vision-based screw detection and torque control must comply with strict regulatory standards to ensure safety and reliability. As the market evolves, manufacturers will need to balance innovation with adherence to regulatory requirements, which may vary across regions and applications.

• Disruption Potential of Different Technologies in Robotic Screwdriving Market: The robotic screwdriving market is being significantly disrupted by emerging technologies such as vision-based screw detection, torque control, robotic arm integration, and autonomous screwfeeding. Vision-based screw detection enables greater precision and reduces errors in screw placement, which is transforming industries like electronics manufacturing. Torque control technology offers enhanced screw-tightening accuracy, making it crucial in sectors like automotive and aerospace where precision is critical. Robotic arm integration enhances the flexibility of robotic screwdriving systems, allowing them to adapt to various tasks across industries, significantly improving efficiency. Autonomous screwfeeding systems eliminate the need for manual screw handling, streamlining assembly lines and reducing human labor. These technologies combined can lead to increased automation, improved productivity, and enhanced product quality in many industries, significantly changing the landscape of manufacturing processes.

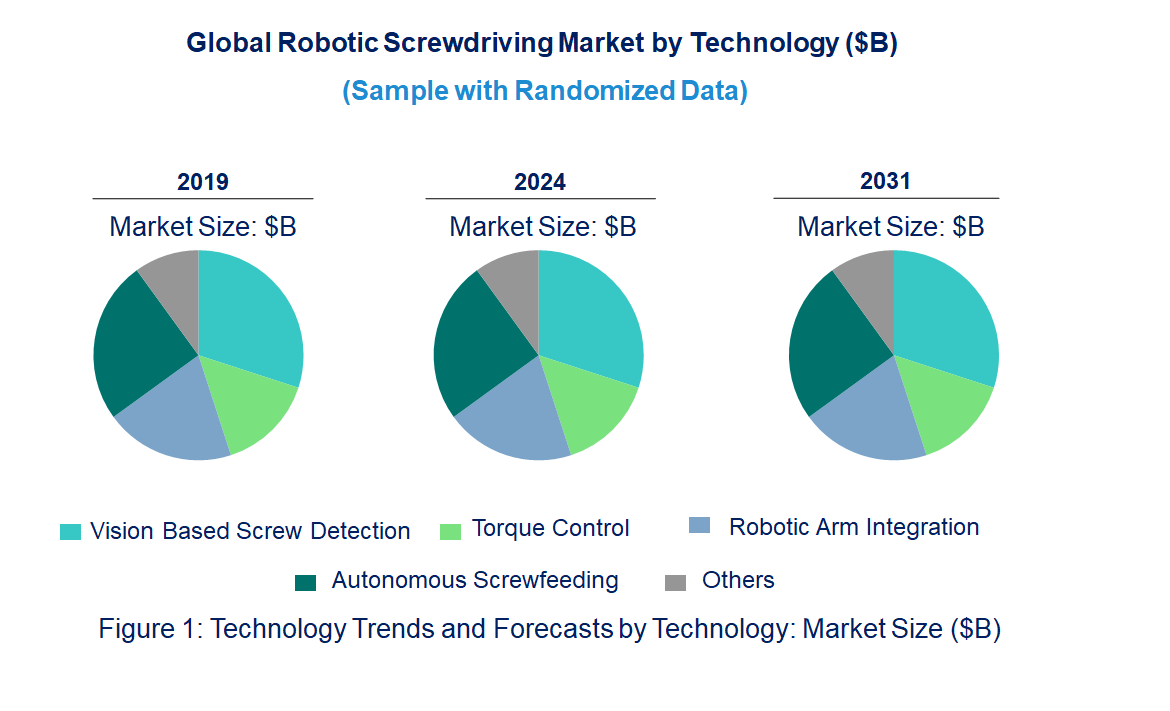

Robotic Screwdriving Market Trend and Forecast by Technology [Value from 2019 to 2031]:

• Vision-based Screw Detection

• Torque Control

• Robotic Arm Integration

• Autonomous Screwfeeding

• Others

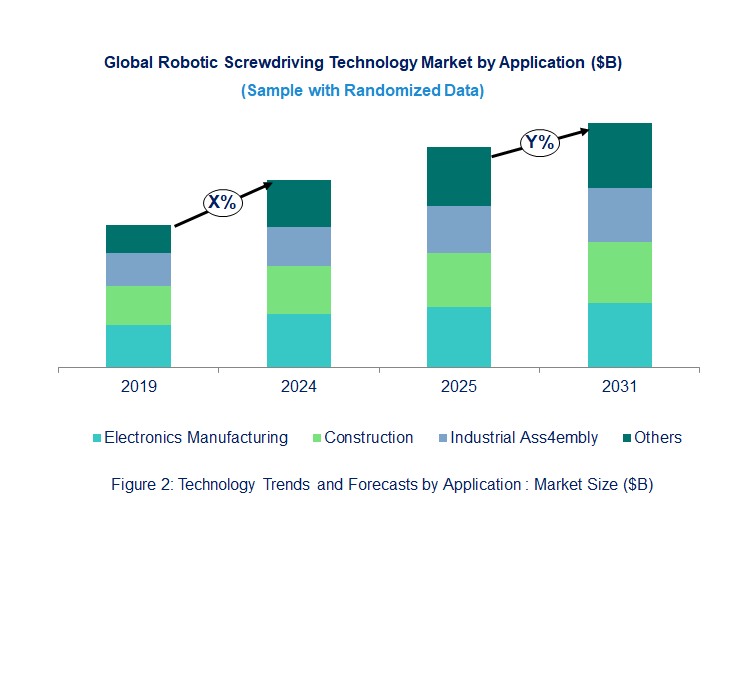

Robotic Screwdriving Market Trend and Forecast by Application [Value from 2019 to 2031]:

• Electronics Manufacturing

• Construction

• Industrial Assembly

• Others

Robotic Screwdriving Market by Region [Value from 2019 to 2031]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

• Latest Developments and Innovations in the Robotic Screwdriving Technologies

• Companies / Ecosystems

• Strategic Opportunities by Technology Type

Features of the Global Robotic Screwdriving Market

Market Size Estimates: Robotic screwdriving market size estimation in terms of ($B).

Trend and Forecast Analysis: Market trends (2019 to 2024) and forecast (2025 to 2031) by various segments and regions.

Segmentation Analysis: Technology trends in the global robotic screwdriving market size by various segments, such as application and technology in terms of value and volume shipments.

Regional Analysis: Technology trends in the global robotic screwdriving market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different applications, technologies, and regions for technology trends in the global robotic screwdriving market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for technology trends in the global robotic screwdriving market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

This report answers following 11 key questions

Q.1. What are some of the most promising potential, high-growth opportunities for the technology trends in the global robotic screwdriving market by technology (vision-based screw detection, torque control, robotic arm integration, autonomous screwfeeding, and others), application (electronics manufacturing, construction, industrial assembly, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which technology segments will grow at a faster pace and why?

Q.3. Which regions will grow at a faster pace and why?

Q.4. What are the key factors affecting dynamics of different technology? What are the drivers and challenges of these technologies in the global robotic screwdriving market?

Q.5. What are the business risks and threats to the technology trends in the global robotic screwdriving market?

Q.6. What are the emerging trends in these technologies in the global robotic screwdriving market and the reasons behind them?

Q.7. Which technologies have potential of disruption in this market?

Q.8. What are the new developments in the technology trends in the global robotic screwdriving market? Which companies are leading these developments?

Q.9. Who are the major players in technology trends in the global robotic screwdriving market? What strategic initiatives are being implemented by key players for business growth?

Q.10. What are strategic growth opportunities in this robotic screwdriving technology space?

Q.11. What M & A activities did take place in the last five years in technology trends in the global robotic screwdriving market?