Low Dielectric Resin Market Trends and Forecast

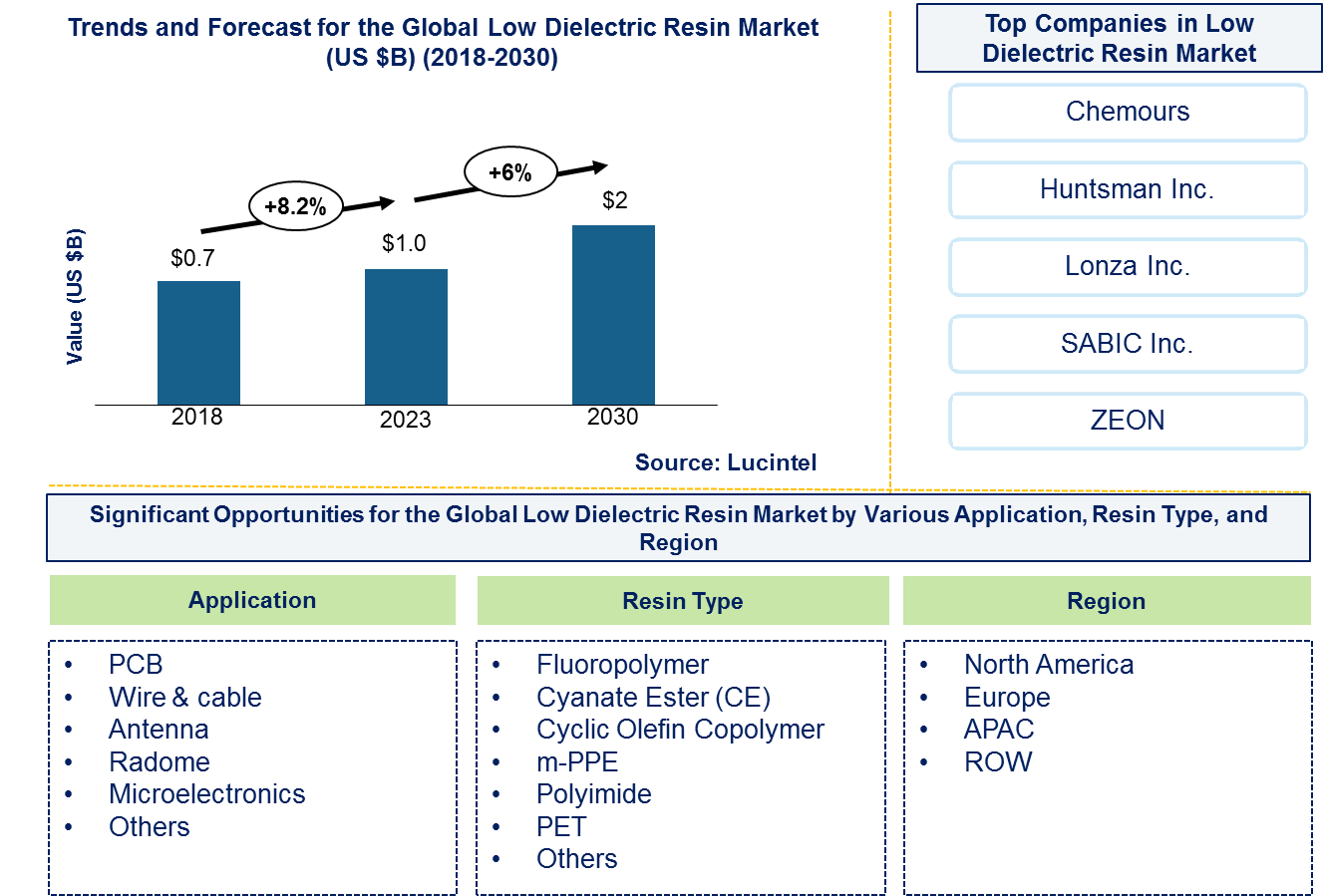

The future of the global low dielectric resin market looks promising with opportunities in the PCB, wire & cable, antenna, microelectronics, and radome applications. The global low dielectric resin market is expected to reach an estimated $2 billion by 2030 with a CAGR of 6% from 2023 to 2030. The major drivers for this market are increasing demand for high performance PCB and growth in wire & cable market.

Polymer types including PTFE, polyimides, PEEK and PPE constitute low dielectric constant resins that are widely used in the electronic industry due to their low electrical permittivity. They have low dielectric constants and thus make excellent electrical insulators. Further additions of fillers such as silica, glass microspheres, and ceramic nanoparticles help reduce dielectric constants even further and improve mechanical strength. Viscosity, curing behavior, and adhesion are adjusted by chemical additives, curing agents, and modifiers respectively. To merge components together solvents are used while cross-linking agents take part in proper polymerization besides improving final resin properties for high frequency applications which require reliability.

• Lucintel forecasts that PCB will remain the largest application segment over the forecast period due to Increasing in communication, defense, RF, and marine industries.

• Fluoropolymer will remain the largest segment and it is expected to witness the highest growth over the forecast period due to growth in the various applications such as high performance PCB, microelectronics, antenna, radome, and wire & cable.

• Asia Pacific is expected to remain the largest region and witness the highest growth over the forecast period

Country wise Outlook for Low Dielectric Resin Market

The low dielectric resin market is witnessing substantial growth globally, driven by increased demand from various application such as PCB, wire & cable, antenna, microelectronics, and radome. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major low dielectric resin producers in key regions: the USA, Canada, Germany, China, India, and Japan.

Emerging Trends in the Low Dielectric Resin Market

Emerging trends in the low dielectric resin market shaping its future applications and market dynamics:

• Increasing Usage of Low Dielectric Resin in the Microfluidic Chips and High Speed PCBs: The demand for microfluidic chips continues to increase as the standards of living increases and technology advancement. Low dielectric resin uses in microfluidic chips for medical safety purpose. Due to low dielectric, transparency, high heat resistance, flame retardant, chemical resistance and low water absorption properties, low dielectric resins are used as microfluidic chips in the healthcare industry.

• Miniaturization in Electronics: Miniaturization in electronics is a key driver influencing the demand for low dielectric resin. As electronic devices become smaller and more compact, there is a growing need for materials with low electrical permittivity to reduce signal loss and interference. Low dielectric resins, such as those based on PTFE or polyimides, enable the design of high-frequency circuits and microelectronic components with improved signal integrity and reliability.

• Growing Demand of High-Frequency Applications: The growing demand for low dielectric resin in high-frequency applications is driven by advancements in telecommunications, aerospace, and automotive industries. These sectors require materials with minimal signal loss and electromagnetic interference (EMI) for efficient operation of radar systems, wireless communication devices, and high-speed data transmission equipment. Low dielectric resins, such as those based on PTFE or polyimides, offer excellent electrical insulation properties while maintaining stability at higher frequencies.

• Smart and Connected Devices: The rise of smart devices and IoT (Internet of Things) technologies is driving the demand for low dielectric resins that can support reliable wireless communication and sensor networks. These resins enable the development of advanced electronic systems with improved signal integrity and reduced electromagnetic interference.

• Advancements in Material Science: Ongoing research and development in material science are leading to innovations in low dielectric resin formulations. Manufacturers are exploring new polymer blends, nanocomposites, and additives to enhance electrical performance, mechanical properties, and process ability of these resins.

A total of 107 figures / charts and 68 tables are provided in this 242-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Development in the Low Dielectric Resin Market

Ongoing innovations and advancements in various sectors of the low dielectric resin market which have been highlighted by recent developments:

Improved Electrical Properties: To achieve lower dielectric constants and reduced loss tangent values, manufacturers are enhancing the dielectric properties of resins. This is crucial for high-frequency circuits and communication systems because it improves signal integrity and attenuates signal.

Enhanced Thermal Stability: Development of low dielectric resins that have improved thermal stability to meet higher operating temperatures without sacrificing electrical performance is getting more attention. This is crucial for automotive electronics, aerospace and industrial equipment applications.

Compatibility with Advanced Manufacturing Processes: There are new resin formulations being created which will be compatible with advanced manufacturing processes such as 3D printing, additive manufacturing, fine pitch electronics assembly among others. Instead this makes possible the production of complex and miniaturized electronic components with precision and reliability.

Sustainability Initiatives: Resin development increasingly focuses on environmental sustainability in terms of using bio-based materials, recycled content, eco-friendly additives etc. The objective is to reduce environmental impacts while meeting green manufacturing regulation requirements.

Integration into 5G Technology: Low dielectric resins are being optimized for 5G technology integration to support development of high-speed data transmission devices, antennas and RF modules. These resins are essential in reducing signal losses so as to ensure reliable connection in the next generation wireless networks.

Advancements in Nanocomposites: Research on nanocomposite materials for low dielectric resins has been continuing. These include nanoparticles which have been used to increase mechanical strength as well as thermal conductivity along with the dielectric properties thus leading to superior performance in demanding electronic applications.

Strategic Growth Opportunities for Low Dielectric Resin Market

The low dielectric resin market is seen as a potential area of growth owing to advancement in technology and increased demand for high-performance materials in the electronics industry. there are several strategic opportunities that can shape its expansion:

• Increasing Need in High-Frequency Applications: The surge of 5G technology, IoT devices and high-speed data communication systems calls for low dielectric resins with improved electric properties. Such resins reduce signal loss and minimize electromagnetic interference (EMI), which is crucial for reliable connectivity in advanced electronic devices. Manufacturers can take advantage of this by innovating on the resin formulation, reducing dielectric constant and improving thermal stability required in high-frequency applications.

• Electronics Miniaturization Trends: Shrinking sizes of electronic gadgets have heightened the call for low dielectric resins capable of miniaturization without compromising performance. Resins must exhibit better mechanical strength, dimensional stability, and compatibility with fine-pitch electronics assembly processes. Therefore, developing resin solutions that aid compactness and dense integration at small scales becomes important to meet the demands for smaller and more efficient devices.

• Materials Science Advancements: There are continued advancements being made within material science that create room for making new resin formulations such as nanocomposites, polymer blends and additives that enhance dielectric properties; thermal management; environmental sustainability etc… Through investment in R&D to develop next generation materials, manufacturers can differentiate themselves in a crowded market.

• Expansion into Emerging Applications: Apart from traditional electronics; emerging applications provide an opportunity for growth within the low dielectric resin market. For example automotive electronics industry now needs materials with lower dielectric constants as well as higher reliability than ever before while aerospace and medical devices industries demand materials with lower dielectric constant among other things used across their products lines. Customizing resin solutions specific application requirements like thermal stability needed by automotive sensors or biocompatibility desired by medical electronics creates room for market growth as well as diversification.

• Sustainability and Regulatory Compliance: The emphasis on sustainability is growing in material sourcing, manufacturing processes and product lifecycle management. Positioning themselves as a focal point for eco-friendly resin formulation using bio-based materials, recycled content, and green additives would allow them to align with global sustainable efforts while meeting regulatory standards. These firms are well placed in the market to address environmentally conscious consumers and businesses.

• Global Market Expansion: Expansion into regions of rapid industrialization and infrastructure development creates growth opportunities for many organizations as they can build their market presence there. In order to penetrate new markets overseas and meet customers’ needs worldwide, it is necessary to establish partnerships, distribution networks, and local production facilities within these areas.

Low Dielectric Resin Market Driver and Challenges

Low dielectric resin has a very important role in many application including PCB, wire & cable, antenna, microelectronics, and radome. The changing market dynamics are being driven by a high demand for high-frequency electronics, shrinking electronic gears and advancements in technology. however, challenges like cost and price competition, material performance and reliability and technological complexity to sustain the market growth.

The factors responsible for driving the low dielectric resin market include:

Growing Demand for High-Frequency Electronics: The demand for low dielectric resins is driven by the increasing adoption of 5G technology, IoT devices and high-speed data communication systems among others. These resins are important in reducing signal loss and electromagnetic interference (EMI) in advanced electronic applications thus maintaining signal integrity.

Shrinking Electronic Gears: As electronic gadgets reduce in size, there will be a rise in the use of low dielectric resins to enable manufacturers achieve miniaturization while still maintaining performance. Various kinds of industries such as telecommunications, automotive electronics and consumer electronics will see smaller, lighter and efficient electronic components to be built from these materials.

Advancements in Technology: Constant technological advancements have led to better electrical properties, thermal stability and compatibility with advanced manufacturing processes for low dielectric resin which has been made possible through material science and resin formulation. This product differentiation caters to ever changing market trends hence driving its adoption.

Regulatory Standards and Environmental Concerns: Increasing regulatory standards on energy efficiency and environmental sustainability have increased the demand for eco-friendly compliant materials. Low dielectric resins that originate from sustainable sources as well as recycled content that does not contain hazardous substances meet global environmental regulations plus consumer preferences.

Challenges facing the low dielectric resin market are:

Cost and Price Competition: However, low dielectric resins cost higher than standard resins; thus making it difficult for them to be adopted widely especially in industries that are price sensitive. In the meantime, there is also competition between producers on prices as performance gains have to justify higher costs.

Material Performance and Reliability: On account of this, ensuring reliable, consistent material performance and durability of low dielectric resins for a range of operational conditions and applications is an uphill task. A successful balancing act should therefore be achieved regarding such properties as e.g. dielectric constant, thermal stability or mechanical strength within resin so that those could reach harsher requirements from industry standards and customers’ anticipations.

Technological Complexity: Therefore, material science competence will be needed in developing and manufacturing high-performance low dielectric resin formulations; however, complex production processes make these incompatible with all other processes. Manufacturers on their part have to learn how to handle complexity in producing resins that would work well with multiple manufacturing processes.

Compatibility with Assembly Processes: These issues pose problems for low dielectric resins because they must work within fine-pitch electronic assembly processes such as soldering, bonding, encapsulation etc. As a result of this fact, the adhesion process has to be done right while considering thermodynamic management and dimensional stability during assembly which are indeed vital for maintaining product reliability/performance.

The low dielectric resin market is crucial across various applications, including PCBs, wire and cable, antennas, microelectronics, and radomes. This market is experiencing dynamic growth driven by the increasing demand for high-frequency electronics, miniaturization of electronic components, and ongoing technological advancements. The rising adoption of 5G technology, IoT devices, and high-speed data communication systems underscores the importance of low dielectric resins in reducing signal loss and electromagnetic interference (EMI), which are vital for maintaining signal integrity in advanced electronics.

Low Dielectric Resin Suppliers and Their Market Share

The market for low dielectric resin is highly competitive, with several key players such as Huntsman Corporation, Lonza Group, ZEON Corporation, SABIC Corporation, and Chemours Company have established their presence in the market and hold a significant market share. To know the current market share of each of major players Contact Us. Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies low dielectric resin companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. low dielectric resin companies profiled in this report includes.

• Huntsman Corporation

• Lonza Group

• ZEON Corporation

• SABIC Corporation

• Chemours Company

These companies have established themselves as leaders in the low dielectric resin industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the low dielectric resin market are evolving, with the entry of new players and the emergence of innovative low dielectric resin. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Low Dielectric Resin by Segment

There is an increasing growth of low dielectric resin market in various segments due to technological advancements and increased application needs. Polymeric resins such as polytetrafluoroethylene (PTFE), polyimide, polyphenylene ether (PPE) are the most prominent resin among others used in high frequency electronic, aerospace, automotive and industrial sectors. Nanocomposites resins are getting popular for their improved electrical and mechanical properties whereas there is also growing trend for eco-friendly formulations using either bio-based or recycled materials. The custom-designed low dielectric resins are continuously being developed within this industry as it caters to specialized applications including medical devices and flexible electronics thus reflecting its distinct and shifting requirements.

This low dielectric resin market report provides a comprehensive analysis of the market's current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including resin type and application. The report offers insights into regional dynamics, highlighting the major markets for low dielectric resin and their growth potentials. The study includes a forecast for the global low dielectric resin market by resin type, application, and region as follows:

Low Dielectric Resin Market by Resin Type [Volume (M lbs) and $M analysis for 2018 – 2030]:

• Fluoropolymer

• Cyanate Ester

• Cyclic Olefin Copolymer

• m-PPE

• Polyimide

• PET

• Others

Low Dielectric Resin Market by Application [Volume (M lbs) and $M analysis for 2018 – 2030]:

• PCB

• Wire & Cable

• Antenna

• Microelectronics

• Radome

• Others

Low Dielectric Resin Market by Region [Volume (M lbs) and $M analysis for 2018 – 2030]:

• North America

• US

• Canada

• Mexico

• Europe

• Germany

• The United Kingdom

• France

• Asia Pacific

• China

• South Korea

• Taiwan

• Japan

• India

• The Rest of the World

• Central and South America

• Middle East and Africa

Features of Low Dielectric Resin Market

• Market Size Estimates: Low dielectric resin market size estimation in terms of value ($B) and volume (M Lbs.) shipment.

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by resin type and application

• Regional Analysis: Low dielectric resin market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different resin type, application and regions for the low dielectric resin market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the low dielectric resin market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in low dielectric resin or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the low dielectric resin market size?

Answer: The global low dielectric resin market is expected to reach an estimated $2 billion by 2030.

Q2. What is the growth forecast for low dielectric resin market?

Answer: The low dielectric resin market is expected to grow at a CAGR of 6% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the low dielectric resin market?

Answer: The major drivers for this market are increasing demand for high performance PCB and growth in wire & cable market.

Q4. What are the major applications or end use industries for facial cleanser?

Answer: PCB will remain the largest application during the forecast period due to increase in demand of high performance PCB in communication, defense, aerospace, and marine industries.

Q5. What are the emerging trends in low dielectric resin market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include increasing uses of low dielectric resin in microfluidic chips for medical device and low dielectric resin in high speed PCBs for low signal loss and high frequency.

Q6. Who are the key low dielectric resin companies?

Answer: Some of the key low dielectric resin companies are as follows:

• Huntsman

• Lonza Group

• Zeon

• SABIC

• Chemours

Q7. Which low dielectric resin product segment will be the largest in future?

Answer: Lucintel forecasts that fluoropolymer will remain the largest resin type and witness the highest growth over the forecast period supported by increase in demand for high performance PCB, wire & cable, and antenna applications.

Q8. In low dielectric resin market, which region is expected to be the largest in next 5 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 5 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global low dielectric resin market by resin type (fluoropolymer, cyanate ester, cyclic olefin copolymer, m-PPE, polyimide, PET, and others), application (PCB, wire & cable, antenna, microelectronics, radome, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?

For any questions related to low dielectric resin market or related to low dielectric resin industry, low dielectric resin companies, low dielectric resin market share, low dielectric resin market analysis, low dielectric resin market size, write Lucintel analyst at email: helpdesk@lucintel.com we will be glad to get back to you soon.