GCC and PCC Market Trends and Forecast

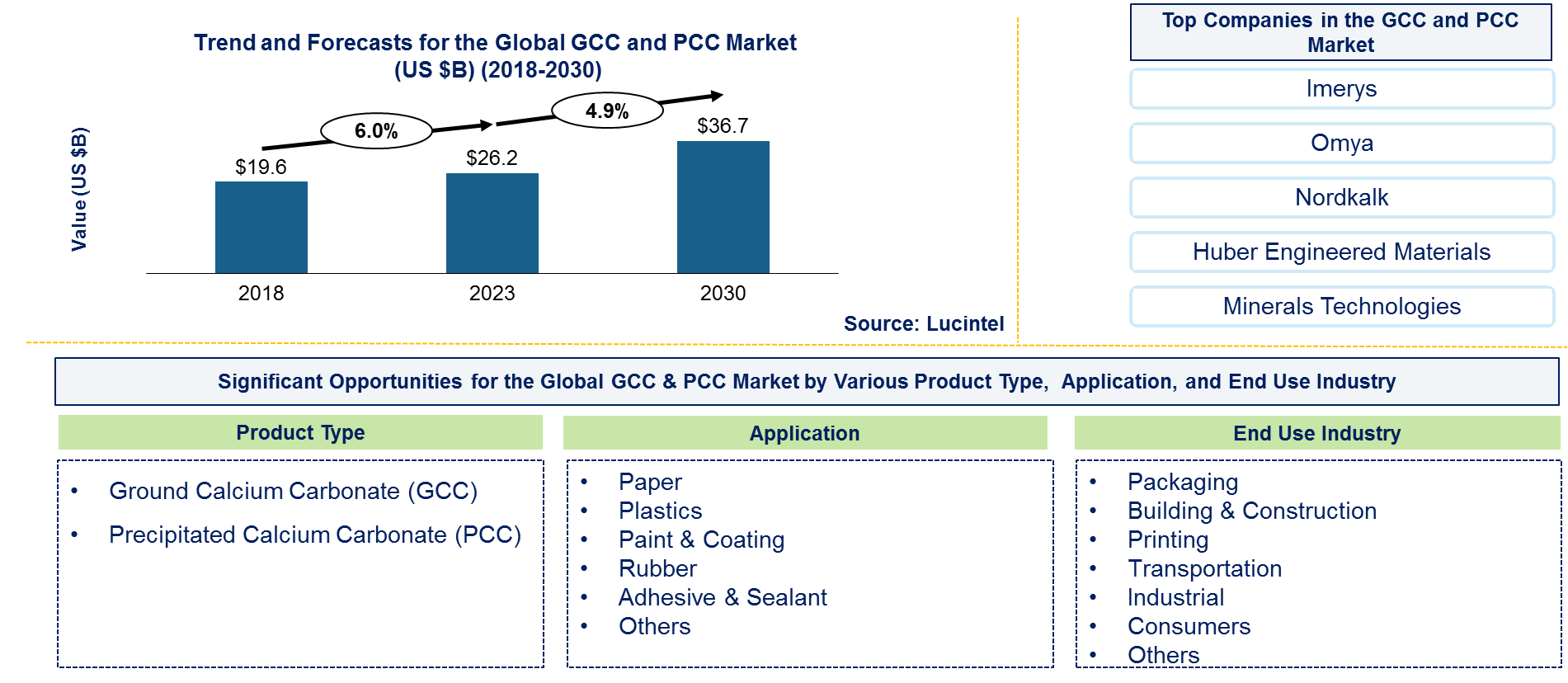

Lucintel finds that the future of the global GCC and PCC market looks good with opportunities in the packaging, building & construction, transportation, and industrial end use industries. The global GCC and PCC market is expected to reach an estimated $37 billion by 2030 with a CAGR of 5% from 2023 to 2030. The major drivers for this market are growing demand for building materials in construction and infrastructure, sustainability and environmental considerations, and expansion of paints & coatings sector.

The main raw materials for GCC and PCC are calcium carbonate (CaCO3) which are acquired from naturally occurring GCC and PCC deposits; these are the most important sources of Ground GCC and PCC (GCC) and Precipitated GCC and PCC (PCC). The raw material for GCC is mechanically ground and reduced in size to produce small particles suitable for different uses within the industry. PCC, on the other hand, is manufactured by a process called chemical precipitation wherein CO2 reacts with Ca(OH)2 to form crystals of calcium carbonate. Depending on their applications in fields like paper making, plastics, paints and coatings, both types of calcium carbonates may contain addition substances or processing agents that enhance specific features such as particle size distribution, brightness or chemical purity.

• Lucintel forecasts that the paper segment will remain the largest application market during the forecast period supported by growth of the packaging and tissue paper market.

• GCC will remain the largest segment due to the growth in plastic and coating applications.

• Asia Pacific is expected to remain the largest market by value and volume and is also expected to witness the highest growth over the forecast period due to the growth in paper and plastics in the APAC region particularly in China and India.

Country wise Outlook for the GCC and PCC Market

The GCC and PCC market is witnessing substantial growth globally, driven by increased demand from various industries such as packaging, building and construction, printing, transportation, industrial, and consumer. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major GCC and PCC producers in key regions: the USA, Germany, China, India, Japan, and Australia.

Emerging Trends in the GCC and PCC Market

The GCC and PCC marketÄX%$%Xs size has been expanding rapidly, driven by the increasing adoption of GCC and PCC in various industries. The market size is influenced by factors such as advances in nanotechnology for the development of nano-sized GCC and PCC particles, surface modification technology for tailored surface properties of GCC and PCC particles, and increasing usage of 3D modelling and virtual reality. The market size is estimated to continue its upward trajectory as industries across the globe seek to improve performance, efficiency, and sustainability.

Emerging trends in GCC and PCC are shaping its future applications and market dynamics:

1. Development of Nano-Sized GCC and PCC Particles Using Advances in Nanotechnology: The development of nano-sized GCC and PCC particles which have high surface area and reactivity for use in high-performance coatings, plastics, and biomedical materials are possible due to advances in nanotechnology.

2. Surface Modification Technologies for Customizable Surface Properties of GCC and PCC Particles: Innovations in surface modification technologies enable customizable surface properties of GCC and PCC particles such as improved polymer compatibility, better dispersion, and optimized rheological properties for different applications.

3. Increasing Adoption of Additives for Improved Functionalization of GCC and PCC: Nowadays, additives such as dispersants, coupling agents and coating agents are increasingly used in the functionalization of GCCs or PCCs to improve their performance including mechanical strength, optical properties, barrier properties (in packaging materials).

4. Green Production Methods for GCC and PCC: Green production methods for GCC and PCC that utilize carbonation techniques with captured CO2 to minimize greenhouse gas emissions and energy consumption have been developed by several companies.

5. Bio-Based Development of Calcium Carbonates: Currently researches are being directed towards the bio-based manufacturing processes of GCCs or PCCs derived from renewable sources like agricultural residues or waste streams instead of conventional mineral-derived calcium carbonates.

These trends reflect ongoing advancements and innovations in GCC and PCC market aimed to address industry demands for improved performance, sustainability, and cost-effectiveness across a wide range of applications including paper, plastics, construction, pharmaceuticals, and environmental remediation.

A total of 129 figures / charts and 109 tables are provided in this 227-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments in the GCC and PCC Market

Recent developments in GCC and PCC market which highlights ongoing innovations and advancements across different sectors:

Technological Advancements: The innovations in the manufacturing processes and equipment to enhance production efficiency, reduce energy consumption, and improve quality of products.

Sustainability Initiatives: Enhanced focus on sustainable procurement of raw materials and environmental friendly manufacturing techniques for regulatory compliance and consumer preferences.

Application Expansion: GCC and PCC have functional advantages that make them increasingly important to industries such as paper, plastics, paints and coatings, pharmaceuticals, and construction.

Market Consolidation: Key players are merging with others, acquiring them or entering into partnerships to consolidate their market share by adding more products in their portfolio as well as exploiting various strengths in terms of distribution channels or technology.

Regional Growth: These economies will continue growing with the likes of Asia Pacific being the fastest due to industrialization driven by urbanization coupled with a rising middle class population which pushes for more requirements hence demand for both GCC and PCC across several end use sectors.

Strategic Growth Opportunities for GCC and PCC Market

The GCC and PCC market is very dynamic due to its unique properties of being versatile with whiteness and brightness, and particle size control. Some key strategic growth opportunities for this market include:

Emerging Economies:

Rapid industrialization, urbanization and infrastructure development are being experienced in emerging economies, specifically Asia-Pacific and Latin America. GCC and PCC are critical in these areas for use in construction materials, paints and coatings, plastics and agriculture among others. As a result of the increasing number of middle-class households as well as disposable incomes rising, demand is also higher for products that contain GCC or PCC such as paper, packaging etc., which create significant opportunities for growth.

Sustainability Focus:

Across different industries there is an ongoing global shift toward sustainability and eco-friendly practices. Naturally sourced (GCC) or produced with lower environmental impact (PCC), offer sustainable advantages. They can act as alternatives to synthetic or environmentally hazardous additives used in biodegradable plastics, eco-friendly packaging materials & green building materials applications among others. There will be companies who through innovation seek to improve the sustainability profile of their GCC & PCC products thus taking advantage of this trend that is growing & becoming more competitive.

Innovative Applications & Product Development:

The range of applications for both GCC & PCC have been widened by continuous research and development efforts. For purity purposes, control over particle size distribution (PSD) and bioavailability concerns; PCC has found increasing uses within cosmetics industry, food & beverages sector or even pharmaceuticals market segments among other sectors too. In agriculture it helps to improve crop yields besides soil health which makes it useful when used as soil conditioner or pH adjuster; hence making it useful in agriculture. On the other hand creating specialty grades like ultra-fine GCC for high performance coating solutions or advanced materials made from nano-sized PCC opens up new avenues for growth.

Technological Advancements:

Advances in manufacturing technologies lead to increased efficiency as well cost effectiveness during production of GCCs and PCCs. Energy consumption levels can be reduced while at the same time improving product quality-consistency through automation, digitalization and optimization. Developing innovative modes of production can help to bring down the overall cost of manufacturing hence making GCC & PCC more affordable relative to alternative materials.

Strategic Partnerships and Market Expansion:

Strategic partnerships, joint ventures and mergers/acquisitions are essential for expanding market reach as well as accessing new geographical markets. Collaborating with downstream industries (e.g., automotive, aerospace & healthcare) for production of tailored solutions using GCC & PCC is able to lead to development of innovative products that will be offered in the marketplace. Furthermore, having many distribution channels with a strong supply chain management and better market responsiveness through good supplier relationships is key.

Regulatory Compliance and Consumer Awareness:

Meeting changing product safety, environmental sustainability or health impacts regulations is paramount. Compliance with certifications as well as standards increases market acceptance by facilitating entry into regulated industries. Educating consumers about GCC & PCC benefits vis-à-vis their applications in conjunction with advertising initiatives are some sure ways of increasing awareness that should eventually result in calling for such products among the people.

Bybtaking advantage of these strategic growth opportunities leveraged by the companies operating within GCC and PCC markets globally could go a long way in making them become key players which drive innovations, sustainability, and profits in different end use applications altogether.

GCC and PCC Market Driver and Challenges

GCC and PCC has a very important role in many applications including paper, plastic, and paint and coating. The changing market dynamics are being driven by the growing demand for building materials in construction and infrastructure, sustainability and environmental considerations, and expansion of paints & coatings sector. however, challenges like intense competition and regulatory compliance and environmental standards to sustain growth and innovation in the GCC and PCC market. The factors responsible for driving the GCC and PCC market include:

• Growing Demand for Building Materials in Construction and Infrastructure: There is a lot of construction work going on currently. The global trend of urbanization and infrastructure improvement projects has resulted in an increase in demand for superior quality building supplies. GCC is mostly used as filler material in concrete and asphalt thereby improving the strength and durability of construction materials. PCC, with its fine particle size and controlled purity, is often used in specialized applications such as coatings and finishes.

• Sustainability and Environmental Considerations: The GCC and PCC markets are also influenced by the rising emphasis on sustainability with increasing global groups embracing green practices. Both derived from natural limestone sources, these two are considered to be environmentally friendly compared to their synthetic counterparts. Regulatory pressures are driving industries towards more sustainable inputs necessitating high demand for both GCC and PCC in application that aim at reducing environmental impacts caused by them.

• Expansion of Paints & Coatings Sector: Paints & coatings industry is being driven by growing consumer preferences coupled with industrial requirements. In addition, they serve as fillers/pigments leading to better opacity, brightness, and texture properties among others (GCC & PCC respectively). Consequently, this growing sector consumes calcium carbonates of both types thus making them indispensable elements during various production processes.

• Technological Developments in the Production: Production technologies for GCC or PCC have greatly improved resulting into enhanced quality of these materials as well their wider usage areas. New processing techniques allow finer particles sizes besides increased levels of purity hence suitability for use in high-performance applications. On top of that there is constant research which helps come up with new uses for both GCC and PCC thus causing market expansion.

• Expanding Applications Across Industries: The diverse applications of these two chemicals make them suitable for different sectors because they can be applied almost everywhere. For example, coming from agriculture where it acts as soil conditioner to food industry where it is a food additive, these diverse uses promote market growth (GCC & PCC). The high demand for them across various industries makes sure that both remain indispensable in those sectors.

• Rising Demand from the Plastics Industry: Increasingly, GCC and PCC are being used as fillers in plastic products to improve their mechanical properties. Therefore they are valuable materials for strength improvement and cost reduction thus, they offer advantages in plastics industry (GCC & PCC). This has increased the demand for these chemicals within this sector.

Challenges facing the GCC and PCC market are:

• Intense Competition: There are very many participants involved in the GCC and PCC markets who struggle to gain market share. Talcs and other fillers fall within examples of such alternative substances. Manufacturers need innovation and product differentiation so as to establish themselves as competitors while also capturing customers regularly.

• Regulatory Compliance and Environmental Standards: It is difficult for GCC or PCC producers to work under strict environmental regulations. Adhering to strict safety measures, companies have had to put up sustainable practices that lead to huge costs when changing technologies (Pandey 2009). Maintaining compliance with shifting rules is essential for continued access into markets without penalties being imposed.

• Price Volatility of Raw Materials: Price fluctuations on raw materials applied in GCC or PCC production have a huge bearing on profitability and pricing strategies. Peaking limestone charges could also increase outlays of power supply necessitated by production processes of various manufacturers yet through limestone prices energy costs too rise among others (Pandey 2009). These risks are supposed to be managed by the enterprises while staying competitive.

• Disruptions in the Supply Chain: Supply chain disruptions can have significant impacts on the production and distribution of GCC and PCC. Production delays and increased costs can be caused by such factors as global occurrences that precipitate disturbances, transportation problems, or lack of raw materials. The companies need to ensure strong supply chain management to minimize these risks and maintain operational efficiency.

• Market Saturation in Selected Areas: In certain markets, particularly developed regions, saturation may hinder growth opportunities for GCC and PCC. It will become increasingly difficult for manufacturers to increase their market share as demand stabilizes. In order to sustain growth in highly saturated areas, companies must look at other markets or find innovative applications.

• Technological Barriers to Entry: However, the technological advancements that drive this growth are also likely to create barriers of entry into the GCC and PCC markets for new comers Established players in the market with high R&D capabilities are likely to have a greater advantage hence locking out small firms without much investment in technology and innovation.

The GCC and PCC markets are dynamic and interrelated, driven by strong demand across multiple industries, technological advancements, and sustainability trends. However, they face significant challenges such as competition from each other, regulatory pressures and market volatility. Understanding these drivers and challenges will enable stakeholders to make informed decisions and come up with strategies that would help them successfully navigate these complex markets.

As both sectors continue to evolve, companies that invest in innovation, sustainability, and robust supply chain management will be better positioned to capitalize on the opportunities presented in the GCC and PCC markets. By proactively addressing their various challenges and taking advantage of growth drivers at hand; businesses can secure themselves a place within this competitive landscape while ensuring sustainable industrial future.

Challenges facing the GCC and PCC market.

GCC and PCC Market Driver and Challenges

GCC and PCC has a very important role in many applications including paper, plastic, and paint and coating. The changing market dynamics are being driven by the growing demand for building materials in construction and infrastructure, sustainability and environmental considerations, and expansion of paints & coatings sector. however, challenges like intense competition and regulatory compliance and environmental standards to sustain growth and innovation in the GCC and PCC market. The factors responsible for driving the GCC and PCC market include:

• Growing Demand for Building Materials in Construction and Infrastructure: There is a lot of construction work going on currently. The global trend of urbanization and infrastructure improvement projects has resulted in an increase in demand for superior quality building supplies. GCC is mostly used as filler material in concrete and asphalt thereby improving the strength and durability of construction materials. PCC, with its fine particle size and controlled purity, is often used in specialized applications such as coatings and finishes.

• Sustainability and Environmental Considerations: The GCC and PCC markets are also influenced by the rising emphasis on sustainability with increasing global groups embracing green practices. Both derived from natural limestone sources, these two are considered to be environmentally friendly compared to their synthetic counterparts. Regulatory pressures are driving industries towards more sustainable inputs necessitating high demand for both GCC and PCC in application that aim at reducing environmental impacts caused by them.

• Expansion of Paints & Coatings Sector: Paints & coatings industry is being driven by growing consumer preferences coupled with industrial requirements. In addition, they serve as fillers/pigments leading to better opacity, brightness, and texture properties among others (GCC & PCC respectively). Consequently, this growing sector consumes calcium carbonates of both types thus making them indispensable elements during various production processes.

• Technological Developments in the Production: Production technologies for GCC or PCC have greatly improved resulting into enhanced quality of these materials as well their wider usage areas. New processing techniques allow finer particles sizes besides increased levels of purity hence suitability for use in high-performance applications. On top of that there is constant research which helps come up with new uses for both GCC and PCC thus causing market expansion.

• Expanding Applications Across Industries: The diverse applications of these two chemicals make them suitable for different sectors because they can be applied almost everywhere. For example, coming from agriculture where it acts as soil conditioner to food industry where it is a food additive, these diverse uses promote market growth (GCC & PCC). The high demand for them across various industries makes sure that both remain indispensable in those sectors.

• Rising Demand from the Plastics Industry: Increasingly, GCC and PCC are being used as fillers in plastic products to improve their mechanical properties. Therefore they are valuable materials for strength improvement and cost reduction thus, they offer advantages in plastics industry (GCC & PCC). This has increased the demand for these chemicals within this sector.

Challenges facing the GCC and PCC market are:

• Intense Competition: There are very many participants involved in the GCC and PCC markets who struggle to gain market share. Talcs and other fillers fall within examples of such alternative substances. Manufacturers need innovation and product differentiation so as to establish themselves as competitors while also capturing customers regularly.

• Regulatory Compliance and Environmental Standards: It is difficult for GCC or PCC producers to work under strict environmental regulations. Adhering to strict safety measures, companies have had to put up sustainable practices that lead to huge costs when changing technologies (Pandey 2009). Maintaining compliance with shifting rules is essential for continued access into markets without penalties being imposed.

• Price Volatility of Raw Materials: Price fluctuations on raw materials applied in GCC or PCC production have a huge bearing on profitability and pricing strategies. Peaking limestone charges could also increase outlays of power supply necessitated by production processes of various manufacturers yet through limestone prices energy costs too rise among others (Pandey 2009). These risks are supposed to be managed by the enterprises while staying competitive.

• Disruptions in the Supply Chain: Supply chain disruptions can have significant impacts on the production and distribution of GCC and PCC. Production delays and increased costs can be caused by such factors as global occurrences that precipitate disturbances, transportation problems, or lack of raw materials. The companies need to ensure strong supply chain management to minimize these risks and maintain operational efficiency.

• Market Saturation in Selected Areas: In certain markets, particularly developed regions, saturation may hinder growth opportunities for GCC and PCC. It will become increasingly difficult for manufacturers to increase their market share as demand stabilizes. In order to sustain growth in highly saturated areas, companies must look at other markets or find innovative applications.

• Technological Barriers to Entry: However, the technological advancements that drive this growth are also likely to create barriers of entry into the GCC and PCC markets for new comers Established players in the market with high R&D capabilities are likely to have a greater advantage hence locking out small firms without much investment in technology and innovation.

The GCC and PCC markets are dynamic and interrelated, driven by strong demand across multiple industries, technological advancements, and sustainability trends. However, they face significant challenges such as competition from each other, regulatory pressures and market volatility. Understanding these drivers and challenges will enable stakeholders to make informed decisions and come up with strategies that would help them successfully navigate these complex markets.

As both sectors continue to evolve, companies that invest in innovation, sustainability, and robust supply chain management will be better positioned to capitalize on the opportunities presented in the GCC and PCC markets. By proactively addressing their various challenges and taking advantage of growth drivers at hand; businesses can secure themselves a place within this competitive landscape while ensuring sustainable industrial future.

GCC and PCC Suppliers and their Market Shares

In this globally competitive market, several key players such as Imerys, Mineral Technologies, Huber, Omya, Nordkalk etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at helpdesk@lucintel.com. Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies GCC and PCC companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the GCC and PCC companies profiled in this report includes.

• Imerys

• Mineral Technologies

• Huber Engineered Materials

• Omya

• Nordkalk

• Lhoist

These companies have established themselves as leaders in the GCC and PCC industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the GCC and PCC market are evolving, with the entry of new players and the emergence of innovative GCC and PCC technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

GCC and PCC Market by Segment

Major segments of GCC and PCC that are experiencing growth include paper, plastics, paints and coatings, rubber, and adhesive and sealant applications. GCC and PCC are widely used as fillers and coating pigments in paper production to improve opacity, brightness, and printability. They serve as functional additives in plastics and polymers to improve mechanical properties such as stiffness, impact resistance, and dimensional stability.

This GCC and PCC market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including application, product type, and end use industry. The report offers insights into regional dynamics, highlighting the major markets for GCC and PCC and their growth potentials. The study includes trends and forecast for the global GCC and PCC market by application, product type, and end use industry, and region as follows:

GCC and PCC Market by Application [Volume (Kilotons) and $M shipment analysis from 2018 to 2030]:

• Paper

• Plastics

• Paint and Coating

• Rubber

• Adhesive and Sealant

• Others

GCC and PCC Market by Product Type [Volume (Kilotons) and $M shipment analysis from 2018 to 2030]:

• Ground Calcium Carbonate (GCC)

• Precipitated Calcium Carbonate (PCC)

GCC and PCC Market by End Use Industry [Volume (Kilotons) and $M shipment analysis from 2018 to 2030]:

• Packaging

• Building and Construction

• Printing

• Transportation

• Industrial

• Consumer

• Others

GCC and PCC Market by Region [Volume (Kilotons) and $M shipment analysis from 2018 to 2030]:

• North America

o US

o Canada

o Mexico

• Europe

o Germany

o Italy

o Spain

• Asia Pacific

o China

o Japan

• The Rest of the World

Features of GCC and PCC Market

Market Size Estimates: GCC & PCC market size estimation in terms of value ($M) and volume (kilotons)

Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

Segmentation Analysis: Market size by application, product type, and end use industry.

Regional Analysis: GCC and PCC market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different application, product type, end use industry, and regions for the GCC and PCC market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for the GCC and PCC market.

If you are looking to expand your business in GCC and PCC or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

FAQ

Q1. What is the GCC and PCC market size?

Answer: The global GCC and PCC market is expected to reach an estimated $37 billion by 2030.

Q2. What is the growth forecast for GCC and PCC market?

Answer: The GCC and PCC market is expected to grow at a CAGR of 5% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the GCC and PCC market?

Answer: The major growth drivers for this market are growing demand for building materials in construction and infrastructure, sustainability and environmental considerations, and expansion of paints & coatings sector.

Q4. What are the major applications or end use industries for GCC and PCC?

Answer: Paper is the major application for calcium carbonate.

Q5. What are the emerging trends in GCC and PCC market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include advances in nanotechnology for the development of nano-sized GCC and PCC particles, surface modification technology for tailored surface properties of GCC and PCC particles, and growing functionalization of various type of additives

Q6. Who are the key GCC and PCC companies?

Answer: Some of the key GCC and PCC companies are as follows:

• Imerys

• Mineral Technologies

• Huber Engineered Materials

• Omya

• Nordkalk

• Lhoist

Q7.Which GCC and PCC product segment will be the largest in future?

Answer: Lucintel forecasts that GCC will remain the largest segment due to the growth in plastic and coating applications.

Q8: In GCC and PCC market, which region is expected to be the largest in next 5 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 5 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global GCC and PCC market by application (paper, plastics, paint & coating, rubber, adhesive and sealant, and others), product (ground calcium carbonate and precipitated calcium carbonate), end use industry (packaging, building and construction, printing, transportation, industrial, consumer, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?