Gantry Robot Market Trends and Forecast

The technologies in the gantry robot market have undergone significant changes in recent years, with a shift from traditional mechanical and pneumatic systems to more advanced technologies such as electric motion control systems and integrated ai-based systems. This shift has been driven by advancements in automation and the increasing demand for precision, efficiency, and flexibility in industrial applications. For example, moving from hydraulic systems to electric actuators has improved energy efficiency and precision in tasks such as handling, welding, and palletizing. Additionally, the integration of machine learning and ai algorithms into gantry systems has allowed for more adaptive and intelligent robots, capable of performing complex tasks with greater autonomy. This transition to more advanced and smarter systems is reshaping the landscape of gantry robotics, providing higher accuracy, faster speeds, and better operational cost-effectiveness.

Emerging Trends in the Gantry Robot Market

The gantry robot market is witnessing several emerging trends that are driving innovation and expanding its potential. Here are five key trends:

• Integration of ai and machine learning: The use of ai and machine learning algorithms is enabling gantry robots to perform more complex and adaptive tasks, making them more intelligent and flexible for various applications.

• Energy-efficient systems: Manufacturers are focusing on developing more energy-efficient gantry robots by replacing hydraulic and pneumatic systems with electric actuators, which consume less power and reduce operational costs.

• Collaborative robotics (cobots): Collaborative gantry robots are being designed to work alongside human operators, enhancing the flexibility and safety of operations in environments such as assembly lines and warehouses.

• Increased customization and flexibility: Gantry robots are becoming more customizable, with modular systems allowing for quick reconfigurations based on the specific needs of different industries and applications, making them more adaptable.

• Enhanced sensors and feedback systems: The use of advanced sensors and feedback systems, such as force/torque sensors, is improving the precision and safety of gantry robots, particularly in delicate handling tasks.

These trends are reshaping the gantry robot market by improving operational efficiency, reducing costs, and enabling greater versatility across a wide range of industries, including manufacturing, logistics, and healthcare.

Gantry Robot Market : Industry Potential, Technological Development, and Compliance Considerations

The gantry robot market has experienced substantial technological advancements, driven by the need for more efficient, precise, and adaptable solutions in industrial automation. These robots are utilized in diverse applications such as handling, palletizing, welding, and more. The evolving technologies within this market offer considerable potential and a high degree of disruption to traditional manufacturing methods.

• Technology Potential:

Gantry robots are poised to revolutionize industries by providing greater precision, higher efficiency, and reduced operational costs. Integration of advanced motion control systems, AI, sensors, and modular components enhances their performance, allowing for quicker adaptation to various applications. The potential for customization and flexibility makes them attractive to industries that require specialized solutions, such as automotive, healthcare, and logistics.

• Degree of Disruption:

These robots disrupt traditional manual processes and older automation systems by offering faster, more accurate, and versatile solutions. Automation with gantry robots reduces human error and improves production timelines, resulting in higher productivity and quality control.

• Level of Current Technology Maturity :

While gantry robots have reached a high level of maturity in certain applications, there are still areas, particularly AI and collaborative robotics, where development continues to advance. Innovations in AI, machine learning, and predictive maintenance are expected to further enhance the market.

• Regulatory Compliance:

As gantry robots integrate more with automation systems, ensuring compliance with industry-specific regulations becomes crucial, particularly in sensitive industries such as healthcare and food manufacturing.

The gantry robot market is evolving rapidly with significant technological advancements. The integration of AI, advanced sensors, and energy-efficient systems holds immense potential, while ongoing innovations will continue to disrupt traditional manufacturing methods, paving the way for further growth and market expansion.

Recent Technological development in Gantry Robot Market by Key Players

Key players in the gantry robot market are actively contributing to the advancements in technology and application. These developments are shaping the market landscape and driving growth.

• Toshiba machine has introduced advanced gantry robots with enhanced motion control systems and integrated ai. This technology improves speed, precision, and adaptability, making the robots more effective for complex industrial tasks such as handling and assembly.

• Liebherr has developed gantry systems with increased payload capacity and high-speed operation, focusing on industries that require heavy lifting, such as construction and automotive manufacturing. Their innovations in modularity make it easier to tailor systems to specific operational needs.

• Gudel has enhanced its gantry robot systems with advanced sensors and feedback systems, improving safety and precision in applications like palletizing and packaging. Their robots are now capable of working in more dynamic environments, responding to real-time data.

• Bosch rexroth focuses on integrating their gantry robots with advanced motion control systems and iot connectivity. These systems allow for better data analysis, predictive maintenance, and enhanced performance tracking, making them ideal for manufacturing environments that require high uptime.

• Yamaha motor has innovated with their linear gantry robots that are designed for high precision and high-speed operations. These systems are popular in applications like electronics assembly, where speed and accuracy are critical.

• Macron dynamics is offering customized gantry systems that include flexible motion control and modular designs, which allow for easy adaptation across various industries, particularly in research and testing environments.

• Iai is focusing on high-speed gantry systems for precision applications, particularly in the automotive industry, where their robots are increasingly integrated into production lines for tasks like welding and material handling.

These companies’ developments reflect the industry’s shift towards greater precision, energy efficiency, and adaptability, which is transforming the gantry robot market.

Gantry Robot Market Driver and Challenges

The gantry robot market is driven by several factors, but also faces challenges that impact its growth. Here’s an analysis of the major drivers and challenges:

The factors responsible fo driving the global gantry robot market are:

• Increasing demand for automation: The growing demand for automation in industries such as manufacturing, logistics, and healthcare is driving the adoption of gantry robots, especially for repetitive and precise tasks.

• Technological advancements: Innovations in motion control systems, sensors, and ai integration are improving the performance and flexibility of gantry robots, enabling them to tackle a wider range of tasks.

• Cost-effectiveness: As gantry robots become more energy-efficient and cost-effective due to advancements in electric actuators and ai, their adoption becomes more feasible for small and medium-sized enterprises.

• Customization and flexibility: The ability to customize gantry systems for specific applications, such as welding, handling, and palletizing, is driving their widespread use across different industries.

Challenges facing the gantry robot market are:

• High initial investment: The cost of acquiring and installing advanced gantry robots can be a significant barrier for smaller companies, limiting their adoption in certain markets.

• Complexity of integration: Integrating gantry robots into existing production lines requires specialized knowledge and can present operational challenges, particularly in older manufacturing environments.

• Skilled workforce shortage: The demand for skilled personnel to operate and maintain advanced gantry robots is rising, which could potentially slow down their adoption in industries lacking skilled labor.

The gantry robot market is being significantly impacted by drivers such as technological advancements and the growing demand for automation, leading to enhanced performance and adoption. However, challenges related to cost and workforce readiness continue to hinder broader market penetration. The market is evolving, and overcoming these challenges will be crucial for further growth.

List of Gantry Robot Companies

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies gantry robot companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the gantry robot companies profiled in this report includes.

• Toshiba Machine

• Liebherr

• Gudel

• Bosch Rexroth

• Yamaha Motor

• Macron Dynamics

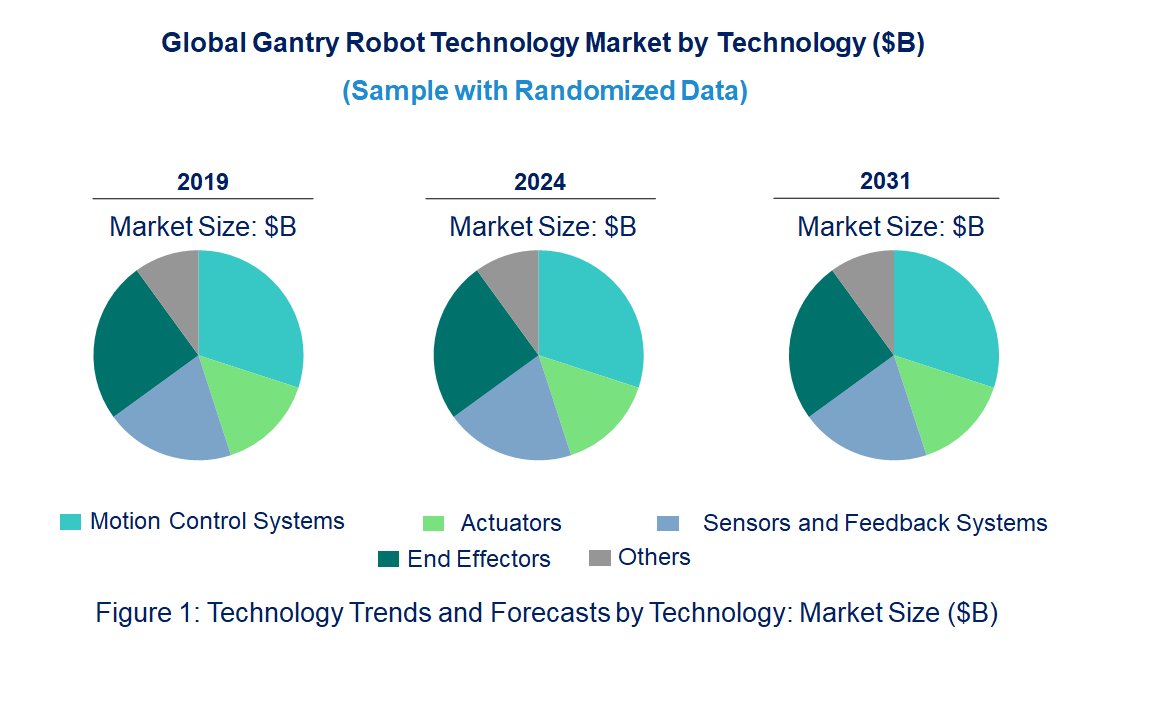

Gantry Robot Market by Technology

• Technology Readiness: Motion control systems and actuators are mature, widely used in many industries. Sensors and feedback systems are advanced, optimizing robot performance in real-time. End effectors are customizable and widely adopted in specialized tasks. However, AI integration is still evolving, and regulatory standards are catching up with technological advancements, especially for industries with strict safety and quality requirements.

• Competitive Intensity and Regulatory Compliance: The market sees high competition in motion control, actuators, and sensors, with companies striving to improve precision, speed, and energy efficiency. Regulatory compliance is crucial, especially in industries like food, healthcare, and automotive, where strict safety standards apply. The integration of AI introduces new regulatory challenges, requiring compliance with emerging frameworks for automation technologies.

• Disruption Potential: Motion control systems, actuators, sensors, feedback systems, and end effectors are driving significant disruption in the Gantry Robot market. Innovations in motion control enable precise and faster operations, while advanced actuators handle heavier payloads. Sensors and feedback systems offer real-time data, improving adaptability and safety. End effectors are becoming more versatile for various tasks, and AI integration enhances operational flexibility, making gantry robots more adaptable across industries.

Gantry Robot Market Trend and Forecast by Technology [Value from 2019 to 2031]:

• Motion Control System

• Actuators

• Sensors and Feedback Systems

• End Effectors

• Others

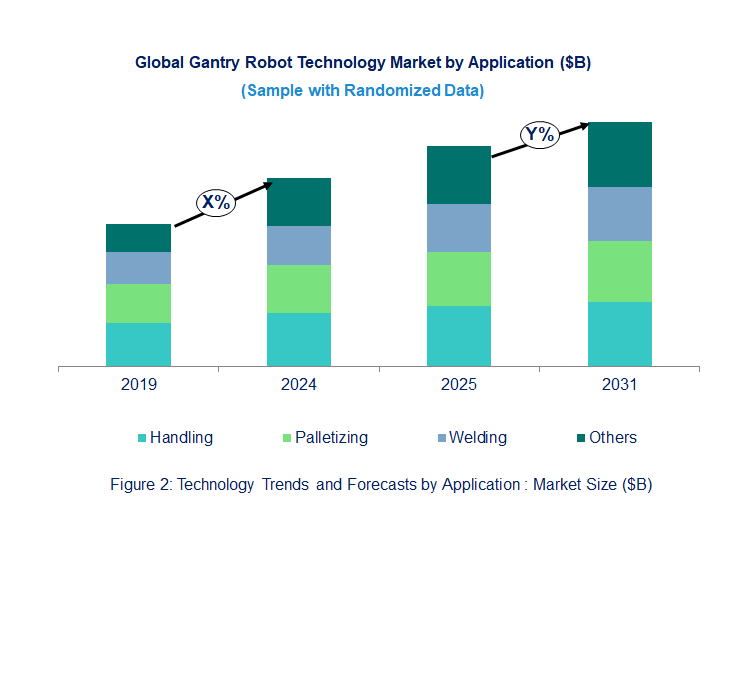

Gantry Robot Market Trend and Forecast by Application [Value from 2019 to 2031]:

• Handling

• Palletizing

• Welding

• Others

Gantry Robot Market by Region [Value from 2019 to 2031]:

• North America

• Europe

• Asia Pacific

• The Rest of the World

• Latest Developments and Innovations in the Gantry Robot Technologies

• Companies / Ecosystems

• Strategic Opportunities by Technology Type

Features of the Global Gantry Robot Market

Market Size Estimates: Gantry robot market size estimation in terms of ($B).

Trend and Forecast Analysis: Market trends (2019 to 2024) and forecast (2025 to 2031) by various segments and regions.

Segmentation Analysis: Technology trends in the global gantry robot market size by various segments, such as application and technology in terms of value and volume shipments.

Regional Analysis: Technology trends in the global gantry robot market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different applications, technologies, and regions for technology trends in the global gantry robot market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for technology trends in the global gantry robot market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

This report answers following 11 key questions

Q.1. What are some of the most promising potential, high-growth opportunities for the technology trends in the global gantry robot market by technology (motion control system, actuators, sensors and feedback systems, end effectors, and others), application (handling, palletizing, welding, and others), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2. Which technology segments will grow at a faster pace and why?

Q.3. Which regions will grow at a faster pace and why?

Q.4. What are the key factors affecting dynamics of different technology? What are the drivers and challenges of these technologies in the global gantry robot market?

Q.5. What are the business risks and threats to the technology trends in the global gantry robot market?

Q.6. What are the emerging trends in these technologies in the global gantry robot market and the reasons behind them?

Q.7. Which technologies have potential of disruption in this market?

Q.8. What are the new developments in the technology trends in the global gantry robot market? Which companies are leading these developments?

Q.9. Who are the major players in technology trends in the global gantry robot market? What strategic initiatives are being implemented by key players for business growth?

Q.10. What are strategic growth opportunities in this gantry robot technology space?

Q.11. What M & A activities did take place in the last five years in technology trends in the global gantry robot market?