Electrically Conductive Adhesive Market Trends and Forecast

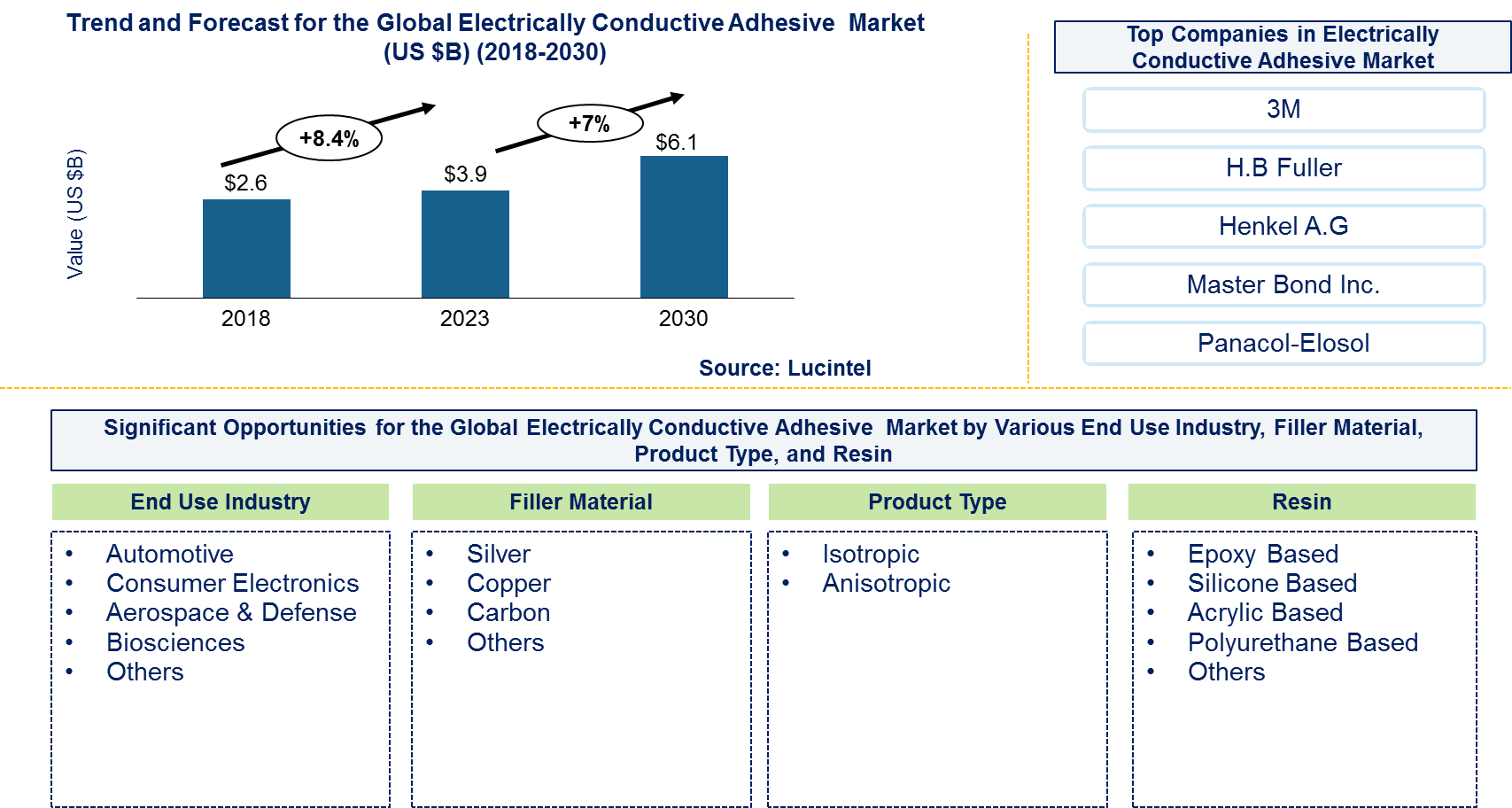

Lucintel finds that the future of the global electrically conductive adhesives market looks promising with opportunities in the industries of consumer electronics, automotive, aerospace and defense, and bioscience. The global electrically conductive adhesives market is expected to reach an estimated $6 billion by 2030 with a CAGR of 7% from 2023 to 2030. The major drivers for this market are growth in the PCBs and semiconductors and replacement of soldering with conductive adhesives due to environmental and health concerns.

Electrically conductive adhesives (ECAs) are specialized adhesives designed to create conductive paths between electronic components, allowing for efficient electrical connections without the need for traditional soldering methods. These adhesives are crucial in various applications, including the assembly of electronic devices, circuit boards, and sensors, where reliable electrical connectivity is essential. The primary raw materials used in the formulation of electrically conductive adhesives include conductive fillers, resin matrices, and curing agents. Conductive fillers, often made from materials like silver, copper, or nickel, are crucial for providing the necessary electrical conductivity.

• Lucintel forecasts that consumer electronics will remain the largest end use industry over the forecast period due to increasing miniaturization of electronic devices and growing production of electronic components

• Silver filled electrically conductive adhesives will remain the largest segment and it is also expected to witness the highest growth over the forecast period due to its beneficial features: silver filled electrically conductive adhesives offer high conductivity and are easily formed and fabricated into the ideal shape.

• Asia Pacific will remain the largest region and it is also expected to witness the highest growth over the forecast period supported by increasing demand for consumer electronic products in China and India.

Country wise Outlook for Electrically Conductive Adhesive Market

The market is witnessing substantial growth globally, driven by increased demand from consumer electronics, automotive, aerospace and defense, and bioscience industries. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major electrically conductive adhesive producers in USA, Germany, China, India, Japan, and Brazil.

Emerging Trends in the Electrically Conductive Adhesive Market

The electrically conductive adhesive market's size has been expanding rapidly, driven by the increasing adoption of electrically conductive adhesive in various applications. The market size is influenced by factors such as development of eco-friendly electrically conductive adhesives and incorporation of innovative conductive fillers in electrically conductive adhesive. The market size is estimated to continue its upward trajectory as industries across the globe seek to improve performance, efficiency, and sustainability.

Emerging trends in electrically conductive adhesive market are shaping its future applications and market dynamics:

1. Eco-Friendly Formulations: The growing concern for the environment has fueled demand for sustainable materials. To this end, manufacturers are producing environmentally friendly ECAs based on non-toxic ingredients, to reduce emissions which may be harmful during production and use, aspects in line with global sustainability goals and regulatory requirements.

2. Advanced Conductive Fillers: The inclusion of new conductive filler materials such as carbon nanotubes, graphene and hybrid materials change how ECAs work. Such fillers enhance electrical conductivity while possibly reducing costs and enhancing mechanical properties resulting in more efficient and dependable adhesive solutions.

3. Thermal Management: The increasing power of electronic devices necessitates proper thermal management. New ECAs are being formulated with high thermal conductivity for easy heat dissipation thereby ensuring durability and improved performance of delicate electronic components.

4. Flexible and Stretchable Adhesives: Flexibility required in wearable electronics leads to creation of stretchable ECAs. These adhesives can retain their electrical properties even when subjected to forces upon them hence making them ideal for smart textiles among other flexible devices.

5. Rapid Curing Technologies: There have been improvements in curing methods such as UV curing, heat-assisted processes that enable faster production cycles by manufacturers of these products. The use of fast-curing ECAs enhances efficiency in manufacturing allowing companies to cope with increased demand without compromising quality.

A total of 127 figures / charts and 113 tables are provided in this 222-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments in Electrically Conductive Adhesive Market

Recent developments in the electrically conductive adhesive market reflect ongoing advancements in technology, expanding applications across industries, and evolving consumer needs.

• Eco-friendly Electrically Conductive Adhesives: The eco-friendly electrically conductive adhesives have been gaining ground recently. As such, manufacturers are increasingly developing adhesives that do not use harmful substances and which can easily be decomposed since they conform with global sustainability initiatives.

• Advanced Encapsulated Fillers: ECAs’ performance is being enhanced by the inclusion of revolutionary fillers like graphene, carbon nanotubes and hybrid composites. These materials exhibit better electrical conductivity, are strong mechanically while cutting on costs.

• High-Performance Applications: In sectors such as automotive, aerospace and medical devices, new ECAs are designed to meet the stringent needs of high-performance applications. These include adhesive products that can withstand great temperature variations and environmental conditions.

• Flexible and Stretchable Adhesives: Development of stretchable ECAs has picked up because of the rise in wearable technology and flexible electronics. This means that the adhesive maintains its electrical function even when it is subjected to mechanical stress thereby making them useful in novel applications.

• Fast Curing Techniques: Progressions in curing methods such as UV curing or moisture curing have made production cycles to become faster. Consequently, this innovation has improved manufacturing efficiency leading to shorter lead times during production

• Integration with Smart Materials: ECAs are being integrated with smart materials having additional functions like self-healing properties as well as sensitivity to environmental changes thus improving overall device performance.

Strategic Growth Opportunities for Electrically Conductive Adhesive Market

Technological advances, regulatory changes and evolving consumer preferences will create strategic growth opportunities for the electrically conductive adhesive market. Below are the key strategic growth opportunities for electrically conductive adhesive:

• Emerging Markets: By entering the developing regions including the Asia-Pacific and Latin America, where we are seeing a growing electronics manufacturing industry and industrialization trends emerge that point to significant growth potential.

• Sustainable Solutions: Thus, it is expected that there will be an increase in demand for eco-friendly glues hence spurring innovation in sustainable formulations which will position firms at the forefront of environmentally responsible practices.

• Flexible and Wearable Electronics: In particular, this has led to a need for using specialized electrically conductive adhesives in flexible and wearable electronics that can perform under mechanical stress.

• Automotive and Aerospace Applications: The use of ECAs in applications involving reliable and lightweight materials is likely to be driven by the increasing acceptance of electric vehicles (EVs) and advanced aerospace technologies.

• Integration with Smart Technologies: This would involve working together with manufacturers of smart devices as well as IoT applications thus increasing their reliance on ECA based electrical interconnections when used within innovative systems.

• Customization and Tailored Products: Thereby, customizing adhesive solutions for specific customers’ needs adds value to market competition while forging long-standing relationships with fabricators.

Electrically Conductive Adhesive Market Driver and Challenges

Electrically conductive adhesive play a crucial role in assembling electronic components, providing reliable electrical connections. The changing market dynamics are being driven by the increasing demand for electronics and technology advancement. However, challenges like material performance variability and regulatory compliance to sustain growth and innovation in access control as a service market. The factors responsible for driving the access control as a service market include:

1. Increasing Demand for Electronics: The growing production of electronic devices, including smartphones, wearables, and automotive applications, drives the need for reliable electrically conductive adhesives.

2. Technology Advancements: Innovations in electronics like IoT and smart technologies require sophisticated adhesive solutions for effective electrical connections to enhance market growth.

3. Trends on Sustainability: Development of eco-friendly materials is essential in order to encourage environmental friendly electrically conductive adhesives’ production.

4. Applications Flexibility: ECAs are able to bond different dissimilar materials, hence can be utilized in various applications including automobile, aerospace and medical industries.

5. Cost efficiency: ECA’s competitive cost versus conventional soldering techniques is favorable for manufacturers looking for ways to optimize their production costs.

Challenges facing the electrically conductive adhesive market are:

1. Material Performance Variability: Variability in the performance of different adhesive formulations can lead to reliability issues, making it essential for manufacturers to ensure consistent quality.

2. Regulatory Compliance: Adhering to stringent regulations regarding material safety and environmental impact can complicate the formulation and approval processes for ECAs.

3. Market Competition: The electrically conductive adhesive market is highly competitive, with numerous players vying for market share, which can lead to price pressures and reduced margins.

4. Integration Issues: Difficulties in integrating ECAs with existing manufacturing processes and equipment can pose challenges for adoption, particularly in established industries.

5. Limited Awareness: There may be a lack of awareness among potential users regarding the benefits and capabilities of ECAs, hindering market penetration in certain sectors.

While the electrically conductive adhesive market is driven by strong demand and technological advancements, it must navigate challenges such as material variability and competitive pressures to ensure sustained growth and innovation.

Electrically Conductive Adhesive Suppliers and their Market Shares

In this globally competitive market, several key players such as Henkel, 3M, H.B. Fuller, Master Bond, Panacol-Elosol, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players, contact us by email at helpdesk@lucintel.com. Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies electrically conductive adhesive companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the electrically conductive adhesive companies profiled in this report includes.

• Henkel AG & Co.

• The 3M Company

• H.B. Fuller Company

• Master Bond Inc.

• Panacol-Elosol Gmbh

These companies have established themselves as leaders in access control as a service industry, with extensive product portfolios, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within electrically conductive adhesive market are evolving, with the entry of new players and the emergence of access control as a service technologies. Additionally, collaborations between raw material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

0

Electrically Conductive Adhesive Market by Segment

Major segments of access control as a service experiencing growth include automotive and consumer electronics industries which contribute to enhancing the features of access control as a service. This electrically conductive adhesive market report provides a comprehensive analysis of the market's current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including by end use industry, filler material, resin, product type, and form. The report offers insights into regional dynamics, highlighting the major markets for electrically conductive adhesive and their growth potentials. The study includes trends and forecast for electrically conductive adhesive market through 2030, segmented by end use industry, filler material, resin, product type, form, and region are as follows:

Electrically Conductive Adhesive Market by End Use Industry [Volume (M lbs) and Value ($M) analysis for 2018 – 2030]:

• Automotive

• Consumer Electronics

• Aerospace and Defense

• Bioscience

• Others

Electrically Conductive Adhesive Market by Filler Material [Volume (M lbs) and Value ($M) analysis for 2018 – 2030]:

• Silver Filler Based Adhesives

• Copper Filler Based Adhesives

• Carbon Filler Based Adhesives

• Others

Electrically Conductive Adhesive Market by Resin [Volume (M lbs) and Value ($M) analysis for 2018 – 2030]:

• Epoxy Based Adhesives

• Silicone Based Adhesives

• Acrylic Based Adhesives

• Polyurethane Based Adhesives

• Others

Electrically Conductive Adhesive Market by Product Type [Volume (M lbs) and Value ($M) analysis for 2018 – 2030]:

• Isotropic Conductive Adhesives

• Anisotropic Conductive Adhesives

Electrically Conductive Adhesive Market by Region [Volume (M lbs) and Value ($M) analysis for 2018 – 2030]:

• North America

o US

o Canada

o Mexico

• Europe

o Germany

o The United Kingdom

o France

o Russia

• Asia Pacific

o China

o Japan

o India

o South Korea

• The Rest of the World

o Brazil

o Argentina

Features of Electrically Conductive Adhesive Market

Market Size Estimates: Electrically conductive adhesive market size estimation in terms of value ($M) and volume (M lbs)

Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

Segmentation Analysis: Market size by end use industry, filler material, resin, product type, and form.

Regional Analysis: Electrically conductive adhesive market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

Growth Opportunities: Analysis of growth opportunities in different end use industry, filler material, resin, product type, form, and regions for the electrically conductive adhesive market.

Strategic Analysis: This includes M&A, new product development, and competitive landscape for the electrically conductive adhesive market.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

FAQ

Q1. What is the electrically conductive adhesive market size?

Answer: The global electrically conductive adhesive market is expected to reach an estimated $6 billion by 2030.

Q2. What is the growth forecast for electrically conductive adhesive market?

Answer: The electrically conductive adhesive market is expected to grow at a CAGR of 7% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the electrically conductive adhesive market?

Answer: The major drivers for this market are growth in the PCBs and semiconductors and replacement of soldering with conductive adhesives due to environmental and health concerns.

Q4. What are the major applications or end use industries for electrically conductive adhesive?

Answer: Consumer electronics is the major end use industries for electrically conductive adhesive .

Q5. What are the emerging trends in electrically conductive adhesive market?

Answer: Emerging trends, which have a direct impact on the dynamics of the electrically conductive adhesives industry, include development of new silicon-based electrically conductive adhesives for automotive sensor and development of flexible electrically conductive adhesives for flexible displays and PCBs.

Q6. Who are the key electrically conductive adhesive companies?

Answer: Some of the key electrically conductive adhesive companies are as follows:

• Henkel AG & Co.

• The 3M Company

• H.B. Fuller Company

• Master Bond Inc.

• Panacol-Elosol Gmbh

Q7.Which electrically conductive adhesive product segment will be the largest in future?

Answer: Lucintel forecasts that silver filled electrically conductive adhesives will remain the largest segment and it is also expected to witness the highest growth over the forecast period due to its beneficial features: silver filled electrically conductive adhesives offer high conductivity and are easily formed and fabricated into the ideal shape.

Q8: In electrically conductive adhesive market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 7 years

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global electrically conductive adhesive market by end use (automotive, consumer electronics, aerospace and defense, biosciences, and others), filler material (silver filler based adhesives, copper filler based adhesives, carbon filler based adhesives, and others), resin (epoxy based adhesives, silicone based adhesives, acrylic based adhesives, polyurethane based adhesives, and others), product type (isotropic conductive adhesives, and anisotropic conductive adhesives), form (paste adhesives and film adhesives), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 5 years in this market?