Conductive Filler Market Trends and Forecast

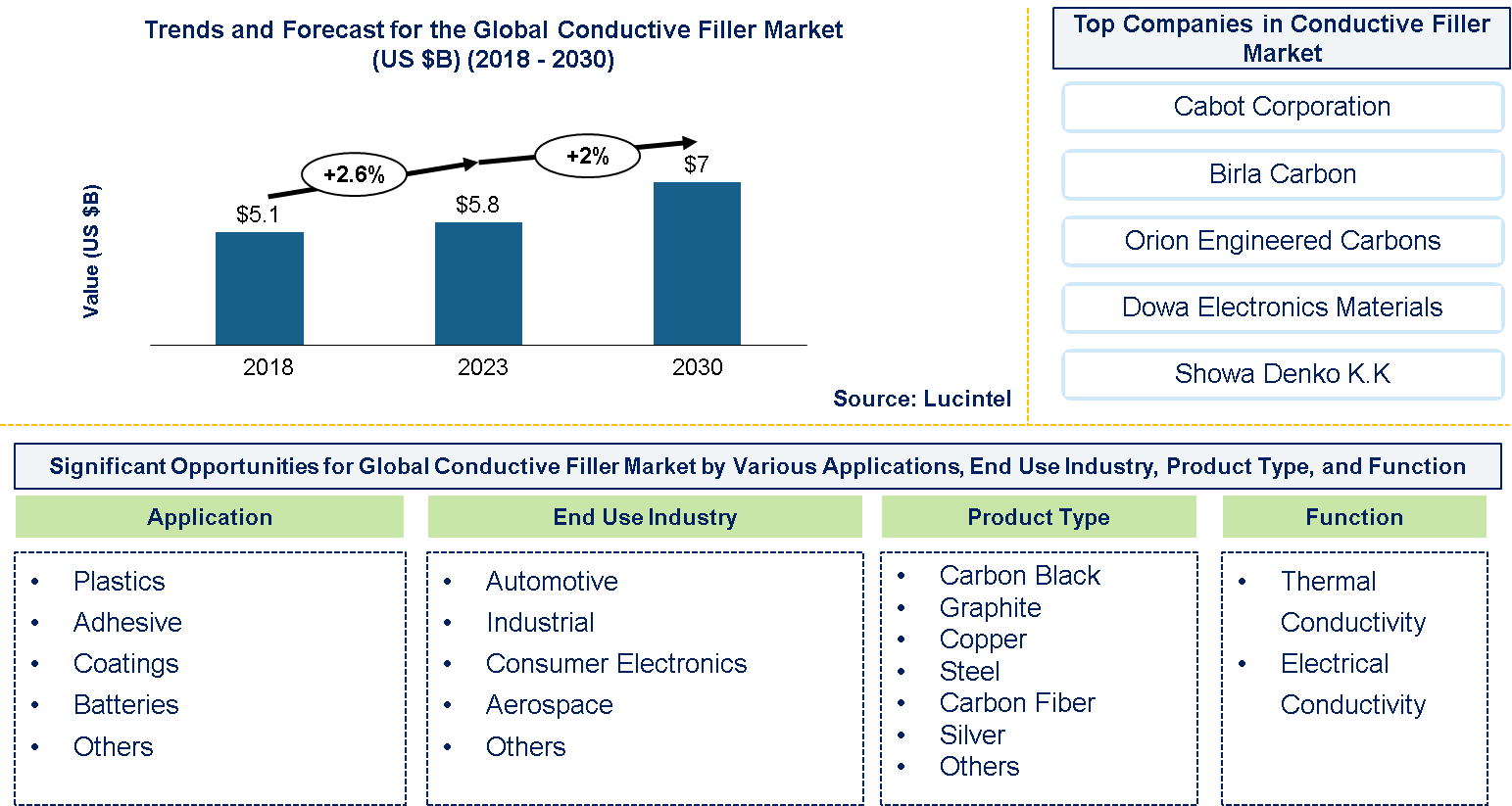

Lucintel finds that the future of the global conductive filler market looks promising with opportunities in the consumer electronics, automotive, industrial, and aerospace industries. The global conductive filler market is expected to reach an estimated $7 billion by 2030 with a CAGR of 2% from 2024 to 2030. The major drivers for this market are increasing demand for conductive fillers in LI-ion batteries to improve the performance, increasing adoption of electric vehicle, growth in consumer electronics and increasing demand for compact, high performance, and high density electronic products.

Conductive fillers, essential for imparting electrical conductivity to polymers and composites, are derived from various raw materials. Metals such as silver, copper, and aluminum are commonly used due to their high electrical conductivity and ease of dispersion in matrices. Carbon-based materials like carbon black, graphite, and carbon fibers offer excellent conductivity and are utilized in applications requiring lightweight and corrosion-resistant properties. Metal oxides such as tin oxide (SnO2) and indium tin oxide (ITO) are preferred for transparent conductive coatings. Polymers can be doped with conductive additives such as polyaniline or polythiophene to enhance conductivity while maintaining flexibility. Additionally, nanomaterials such as graphene and carbon nanotubes provide exceptional conductivity and are employed in high-performance electronic devices and advanced composite materials.

Price of conductive filler can vary significantly based on the type of filler—such as metals (e.g., silver, copper), carbon-based materials (e.g., carbon black, graphite), or nanomaterials (e.g., graphene, carbon nanotubes)—each with distinct conductivity levels and manufacturing costs. Metals like silver are typically more expensive due to their superior conductivity but are balanced against alternatives like carbon black, which offer lower cost but different performance characteristics.

• Lucintel forecasts that silver will remain the largest filler type by value and carbon black will remain the largest filler by volume. Growth in demand for conductive adhesive for semiconductor packaging application will drive the silver filler market.

• Consumer electronics will remain the largest end use industry during the forecast period supported by increasing demand for conductive fillers in EMI/RFI and ESD/Antistatic application in consumer electronics and growth in wearable electronics, portable computers, LED, and smart television.

• Asia Pacific will remain the largest region by value and volume and it is also expected to witness the highest growth over the forecast period supported by growth in consumer electronics and automotive industries.

Country wise Outlook for the Conductive Filler Market

The conductive filler market is witnessing substantial growth globally, driven by increasing use of conductive fillers in electronic components such as printed circuit boards (PCBs), sensors, and displays. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major conductive filler producers in key regions: the USA, Germany, China, India, Japan, and Brazil.

Emerging Trends in the Conductive Filler Market

Emerging trends in the phase change material market shaping its future applications and market dynamics:

• Nanotechnology Integration: Advancements in nanomaterials such as graphene and carbon nanotubes, offering superior conductivity and mechanical properties, suitable for high-performance applications in electronics and aerospace.

• Flexible and Stretchable Electronics: Development of conductive fillers that enable flexibility and stretchability in electronic components, supporting the trend towards wearable technology and flexible displays.

• Bio-based Conductive Materials: Research into bio-based conductive fillers derived from renewable sources, addressing sustainability concerns and reducing reliance on traditional petroleum-based materials.

• 3D Printing Applications: Utilization of conductive fillers in additive manufacturing processes to create complex, custom-designed electronic components and sensors with enhanced conductivity.

• Smart Materials and IoT Devices: Integration of conductive fillers in smart materials and Internet of Things (IoT) devices for real-time data sensing, monitoring, and communication in diverse industrial and consumer applications.

• Enhanced Thermal Management: Innovations in conductive fillers for improved thermal management solutions, crucial for maintaining optimal operating temperatures in electronics, automotive, and renewable energy systems.

A total of 107 figures / charts and 68 tables are provided in this 205-page report to help in your business decisions. A sample figure with insights is shown below.

Recent Developments in the Conductive Filler Market

Ongoing innovations and advancements in various sectors of the conductive filler market which have been highlighted by recent developments:

• Growing Demand for Electrically Conductive Adhesives (ECAs): There has been an increasing demand for electrically conductive adhesives (ECAs) in various industries such as electronics, automotive, and aerospace. Recent developments in the conductive filler market include the introduction of novel filler materials, improved formulation techniques, and advancements in curing methods to enhance the conductivity, adhesion, and reliability of ECAs.

• Advancements in Nanomaterial-Based Fillers: Nanomaterial-based fillers such as carbon nanotubes (CNTs), graphene, and silver nanoparticles continue to drive innovation in the conductive filler market. Recent developments include the development of functionalized nanomaterials with improved dispersion, compatibility, and conductivity for use in applications such as printed electronics, flexible circuits, and electromagnetic interference (EMI) shielding.

• Expansion of Polymer Composite Applications: Conductive fillers are widely used in polymer composites to impart electrical conductivity, thermal conductivity, and electromagnetic shielding properties. Recent developments include the incorporation of conductive fillers such as carbon black, carbon fibers, and metal powders into polymer matrices to enhance the performance of composite materials used in automotive parts, electronic enclosures, and aerospace components.

• Focus on Sustainable and Eco-Friendly Solutions: ThereÄX%$%Xs a growing emphasis on sustainability and environmental responsibility in the conductive filler market. Recent developments include the introduction of eco-friendly filler materials derived from renewable sources, recycled materials, or bio-based polymers to reduce the environmental footprint of conductive filler products.

• Innovation in Printable Electronics and Flexible Substrates: Printable electronics and flexible substrates represent emerging markets for conductive fillers. Recent developments include the formulation of conductive inks and pastes containing conductive fillers for inkjet printing, screen printing, and 3D printing of electronic circuits on flexible substrates such as paper, plastics, and textiles.

• Integration of Conductive Fillers in Energy Storage Devices: Conductive fillers play a crucial role in enhancing the electrical conductivity and mechanical properties of electrodes in energy storage devices such as lithium-ion batteries, supercapacitors, and fuel cells. Recent developments include the optimization of conductive filler morphology, surface chemistry, and distribution to improve the performance and durability of energy storage systems.

Strategic Growth Opportunities for Conductive Filler Market

The conductive filler market is a key player in enabling miniaturization, high performance, and functionality in various electronic devices. Some key strategic growth opportunities for this market include:

Innovation in Material Science:

• Next-Generation Fillers: Developing new conductive fillers with superior conductivity, thermal properties, and dispersability will enhance the performance of conductive pastes and adhesives. This could involve exploring materials like nanocarbons (carbon nanotubes, graphene) or exploring composite fillers with synergistic properties.

• Focus on Sustainability: Sustainability is a growing concern. Research into bio-based or recycled conductive fillers can create eco-friendly alternatives to traditional materials, appealing to environmentally conscious manufacturers and consumers.

• Tailored Solutions: Developing a diverse portfolio of conductive fillers catering to specific applications will be crucial. This could involve fillers optimized for high thermal conductivity in power electronics, or those with superior EMI shielding capabilities for sensitive electronic components.

Expanding Application Landscape:

• Emerging Technologies: The rise of electric vehicles (EVs), 5G infrastructure, and wearable electronics presents exciting opportunities. Conductive fillers play a vital role in these applications, and manufacturers can capitalize by developing specialized fillers optimized for these fast-growing sectors.

• Medical Devices and Implants: Conductive fillers can contribute to advancements in medical devices by enabling miniaturized components and improved signal transmission. Exploring biocompatible and flexible conductive fillers can unlock possibilities in implantable devices and medical wearables.

• 3D Printing Integration: The integration of conductive fillers with 3D printing materials can create functional and conductive printed electronics. This opens doors for customized electronic components and rapid prototyping, fostering innovation across industries.

Regional Market Expansion:

• Focus on Asia Pacific: The Asia Pacific region is a major electronics manufacturing hub with a high demand for conductive fillers. Strategic partnerships or local production facilities can cater to this growing market and ensure faster response times to regional needs.

• Untapped Potential in Emerging Economies: Emerging economies in Africa and South America present potential for future growth. Investing in market research and building relationships with local companies can help establish a foothold in these developing markets.

Collaboration and Strategic Partnerships:

• Academia-Industry Collaboration: Partnerships with research institutions can accelerate the development of novel conductive filler materials and their integration into existing or emerging applications.

• End-to-End Partnerships: Collaboration between conductive filler manufacturers, material suppliers, and electronics manufacturers can foster a collaborative ecosystem. This can lead to the development of optimized conductive pastes and adhesives tailored to specific electronic device needs.

By capitalizing on these strategic growth opportunities, the conductive filler market can solidify its position as a crucial enabler in the ever-evolving world of electronics. Innovation, diversification, and a focus on sustainability will pave the way for the continued success of this dynamic market.

Conductive Filler Market Driver and Challenges

The conductive filler market is influenced by several drivers and faces specific challenges that impact its growth and adoption:

The factors responsible for driving the conductive filler market include:

1. Increasing Demand in Electronics: The growing use of electronic devices and components, such as printed circuit boards (PCBs), flexible electronics, and integrated circuits (ICs), drives the demand for conductive fillers. These fillers enhance electrical conductivity, thermal management, and mechanical strength in electronic applications.

2. Rising Automotive Sector: The automotive industry increasingly integrates conductive fillers in electric vehicles (EVs), sensors, and electronic control units (ECUs) to improve performance, connectivity, and safety features. This sectorÄX%$%Xs expansion contributes significantly to the demand for advanced materials with superior conductivity and durability.

3. Emerging Applications in Energy Storage: Conductive fillers are crucial in energy storage applications, including batteries and supercapacitors, where they enhance conductivity, cycle life, and energy efficiency. As renewable energy sources and electric grid stability become priorities, the demand for high-performance materials in energy storage systems grows.

4. Advancements in Nanotechnology: Innovations in nanomaterials and nanotechnology have led to the development of conductive fillers with enhanced properties such as high conductivity, low weight, and improved dispersibility. These advancements drive the adoption of conductive fillers in high-tech industries, including aerospace, defense, and telecommunications.

5. Regulatory Requirements: Increasing regulations aimed at reducing environmental impact and enhancing product safety drive innovation in conductive filler materials. Materials that meet stringent regulatory requirements while maintaining performance standards are in high demand across various industries.

Challenges facing the conductive filler market are:

1. Cost and Price Volatility: The cost of raw materials and manufacturing processes for conductive fillers can be significant, impacting overall product cost and market competitiveness. Price volatility in raw material markets further complicates cost management for manufacturers.

2. Compatibility and Integration: Integrating conductive fillers into diverse applications, such as polymers, coatings, and composites, requires compatibility testing and careful formulation to ensure optimal performance and durability. Challenges in achieving uniform dispersion and maintaining material properties can hinder adoption.

3. Environmental and Health Concerns: Some conductive fillers may contain hazardous substances or pose environmental and health risks during production, use, or disposal. Addressing these concerns and complying with regulations related to material safety and environmental sustainability are critical challenges for market participants.

Conductive Filler Suppliers and Their Market Shares

In this globally competitive market, several key players such as Cabot Corporation, Showa Denko, Orion, Nippon Light Metal, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players contact us.

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies conductive filler companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the conductive filler companies profiled in this report includes.

• Cabot Corporation

• Showa Denko K.K

• Orion Engineered Carbon

• Birla Carbon

• Imerys

• Nippon Light Metal

• Dowa Electronics

• Asbury Carbon

• Almatis Corporation

These companies have established themselves as leaders in the conductive filler industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations. The market share dynamics within the conductive filler market are evolving, with the entry of new players and the emergence of innovative conductive filler technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Conductive Filler Market by Segment

The conductive filler market is experiencing significant growth across several key segments. Primarily, automotive applications are expanding, particularly in electric vehicles (EVs) and automotive electronics, to enhance energy efficiency and performance. Additionally, energy storage solutions, including batteries and supercapacitors, utilize conductive fillers to improve conductivity and energy density, supporting renewable energy integration efforts. Aerospace and defense sectors are adopting these materials for EMI shielding and lightweight composites, further fueling market growth.

This conductive filler market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. It covers various segments, including application, end use, product, and function. The report offers insights into regional dynamics, highlighting the major markets for conductive filler and their growth potentials. The study includes trends and forecast for the global conductive filler market by application, end use, product, function, and region as follows:

Conductive Filler Market by Product [Value ($M) and Volume (Kilotons) Analysis for 2018 – 2030]:

• Carbon Black

• Graphite

• Carbon Fiber

• Alumina

• Copper

• Silver

• Steel

• Others

Conductive Filler Market by End Use Industry [Value ($M) and Volume (Kilotons) Analysis for 2018 – 2030]:

• Consumer Electronics

• Automotive

• Industrial

• Aerospace

• Others

Conductive Filler Market by Application [Value ($M) and Volume (Kilotons) Analysis for 2018 – 2030]:

• Plastics

• Adhesives

• Coatings

• Battery

• Others

Conductive Filler Market by Function [Value ($M) and Volume (Kilotons) Analysis for 2018 – 2030]:

• Electrical Conductivity

• Thermal Conductivity

Conductive Filler Market by Region [Value ($M) and Volume (Kilotons) Analysis for 2018 – 2030]:

• North America

o US

o Canada

o Mexico

• Europe

o Germany

o Italy

o Russia

• Asia Pacific

o China

o Japan

o India

• The Rest of the World

Features of Conductive Filler Market

• Market Size Estimates: Conductive filler market size estimation in terms of value ($M) and Volume (Kilotons)

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Market size by application, end use, product, and function

• Regional Analysis: Conductive filler market breakdown by North America, Europe, Asia Pacific, and the Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different application, end use, product, function, and regions for the conductive filler market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape for the conductive filler market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

FAQ

Q1. What is the conductive filler market size?

Answer: The global conductive filler market is expected to reach an estimated $7 billion by 2030.

Q2. What is the growth forecast for conductive filler market?

Answer: The conductive filler market is expected to grow at a CAGR of 2% from 2024 to 2030.

Q3. What are the major drivers influencing the growth of the conductive filler market?

Answer: The major drivers for this market are increasing demand for conductive fillers in LI-ion batteries to improve the performance, increasing adoption of electric vehicle, growth in consumer electronics and increasing demand for compact, high performance, and high density electronic products.

Q4. What are the major applications or end use industries for conductive filler?

Answer: Plastic, adhesives, coatings, battery, and others are the major application for conductive filler.

Q5. What are the emerging trends in conductive filler market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include increasing demand of carbon nanotube for electrical conductivity and development of low cost solution such as silver-coated copper filler to reduce the cost of precious metal based filler.

Q6. Who are the key conductive filler companies?

Answer: Some of the key conductive filler companies are as follows:

• Cabot Corporation

• Showa Denko K.K

• Orion Engineered Carbon

• Birla Carbon

• Imerys

• Nippon Light Metal

• Dowa Electronics

• Asbury Carbon

• Almatis Corporation

Q7.Which conductive filler product segment will be the largest in future?

Answer: Lucintel forecasts that silver will remain the largest filler type by value and carbon black will remain the largest filler by volume. Growth in demand for conductive adhesive for semiconductor packaging application will drive the silver filler market

Q8. In conductive filler market, which region is expected to be the largest in next 7 years?

Answer: Asia Pacific is expected to remain the largest region and witness the highest growth over next 7 years.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following 11 key questions

Q.1 What are some of the most promising potential, high growth opportunities for the global conductive filler market by product (carbon black, graphite, carbon fiber, alumina, copper, silver, steel, and others), application (plastics, adhesives, coatings, battery and others), end use industry (consumer electronics, automotive, industrial, aerospace, and others), function type (electrical and thermal), and region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q. 2 Which segments will grow at a faster pace and why?

Q.3 Which regions will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges of the market?

Q.5 What are the business risks and threats to the market?

Q.6 What are the emerging trends in this market and the reasons behind them?

Q.7 What are the changing demands of customers in the market?

Q.8 What are the new developments in the market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M & A activities have taken place in the last 7 years in this market?