Composites in the Global Aerospace Interior Market Trends and Forecast

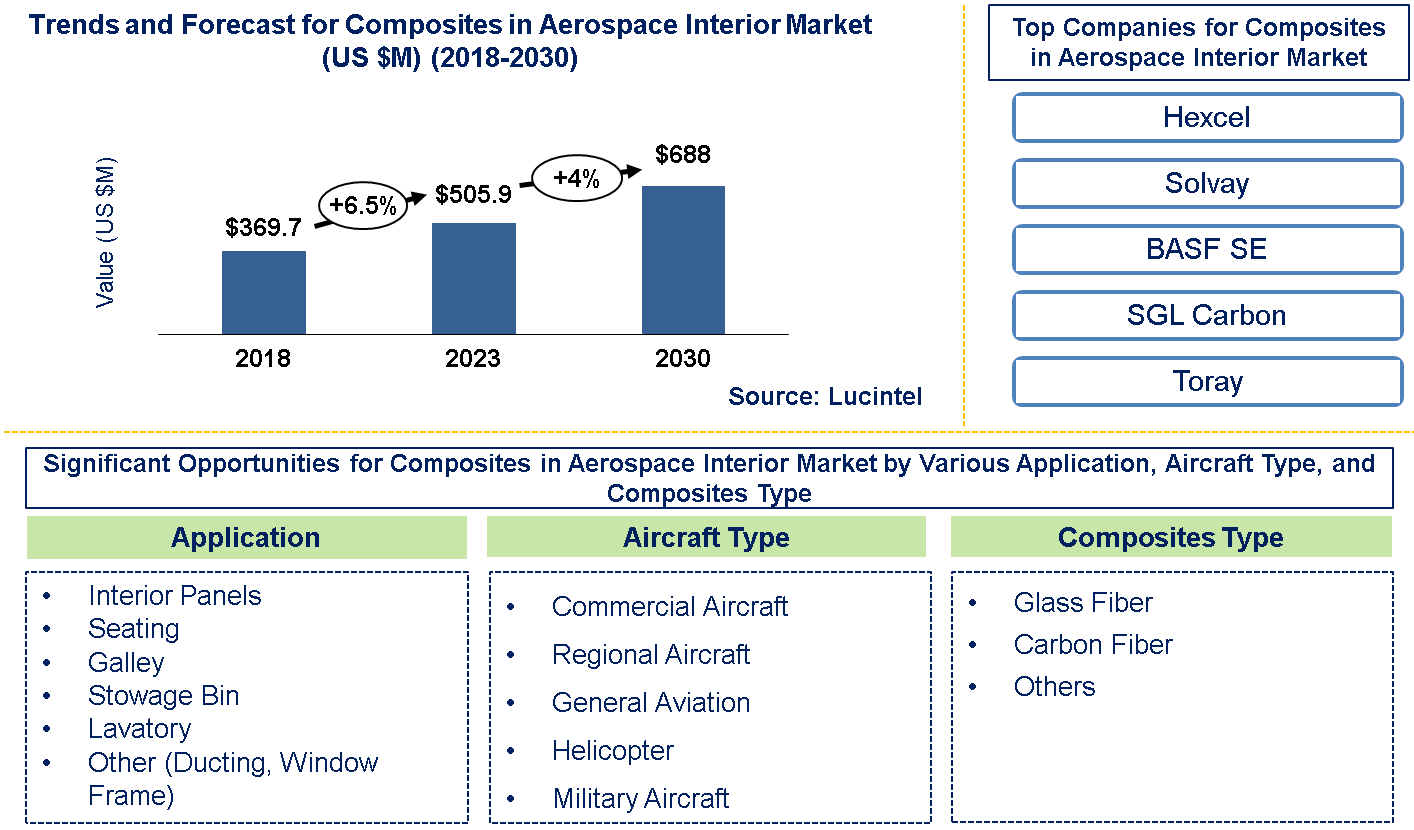

Lucintel finds that the future of composites material in the global aerospace interior market looks promising with opportunities in the commercial aircraft, regional aircraft, general aviation, helicopter, and military aircrafts. Composites in the global aerospace interior market is expected to reach an estimated $688 million by 2030 with a CAGR of 4% from 2023 to 2030. The major growth drivers for this market are increasing deliveries of aircraft and the demand for lightweight materials.

Aerospace interior composite materials typically include carbon fibers, fiberglass, aramid fibers (such as Kevlar) and various resins (epoxy, phenolic etc.). These substances are chosen for their lightweight qualities, high strength-to-weight ratios and fire-resistant properties. Moreover, fillers and additives like nanomaterial or flame-retardant agents are applied to improve certain features such as fire resistance or mechanical strength. In the case of aerospace interiors, these composites play a crucial role in terms of weight reduction, fuel economy boost and cabin components integrity and safety. Composites used for aerospace interiors are more expensive than traditional materials such as metals or plastics. The higher costs arise from the costs of raw materials like carbon fibers and special resins, as well as the complex processes of manufacture. However, weight reduction, improved fuel efficiency and enhanced performance often make such investments worthwhile in aerospace. In order to remain competitive in the aerospace industry, manufacturers keep on coming up with better manufacturing techniques plus efficient material use so as to reduce costs.

• Lucintel forecasts that the interior panels will remain the largest application over the forecast period. The major parts fabricated from composites include floor panels, ceiling panels, sidewalls and partition walls. Increased focus on weight reduction and fuel efficiency by aircraft manufacturers has augmented the use of composites in aircraft interior.

• Europe is expected to remain the largest region over the forecast period due to a significant increase in aircraft deliveries and increasing demand for lightweight materials. APAC is expected to witness the highest growth in forecast period.

Country wise Outlook for the Composites in the Global Aerospace Interior Market

Composites in the global aerospace interior market is witnessing substantial growth globally, driven by increased demand from various markets such as commercial aircraft, regional aircraft, general aviation, helicopter, and military aircraft. Major players in the market are expanding their operations and forming strategic partnerships to strengthen their positions. Below image highlights recent developments by major composites in the global aerospace interior producers in key regions: the USA, UK, China, and Germany.

Emerging Trends in the Composites in the Global Aerospace Interior Market

Emerging trends in composites in the global aerospace interior market shaping its future applications and market dynamics:

• Increased Use of Thermoplastic Composites: Thermoplastic composites are increasingly used in the production of seat frames, panels, and other interior components because they can be recycled, have shorter processing times and can be reshaped and repaired.

• Adoption of Nano-composites: Incorporation of nanomaterials into composites improves mechanical properties, thermal stability and flame retardancy such as lighter, stronger and more durable interior parts.

• Advancement of 3D printing: Additive manufacturing with 3D printing is transforming composites production; making it possible to produce composite parts through this technology. This allows complex structures to be built at low weights using less material and leading to faster orders thereby encouraging innovative interiors.

• Developing Hybrid Composites: Combining various kinds of fibers like glass or carbon fibers in order to create hybrid composites that demonstrate higher strength, flexibility and impact resistance. Such materials are designed for specified applications within the aircraft interiors.

• Integration of Smart Composites: Embedding sensors and other smart technologies in these materials enables real-time monitoring of structural health. It is enhancing maintenance strategies and improving safety protocols within the aerospace industry.

A total of 127 figures / charts and 93 tables are provided in this 158-page report to help in your business decisions. Sample figures with some insights are shown below.

Recent Developments in Composites in the Global Aerospace Interior Market

Ongoing innovations and advancements in various sectors of composites in the global aerospace interior market which have been highlighted by recent developments:

• Automation in Manufacturing: The adoption of automated manufacturing processes such as robotic lay-up and resin transfer molding has promoted consistency, efficiency, and reliability in the manufacture of composite parts.

• Bio-based Composites: Systematic efforts have been made towards developing bio-based composites from renewable resources that are consistent with sustainability goals thereby reducing the environmental footprints on interior components used in aviation.

• Improved Fire Safety: Development of advanced fire resistant composite materials that meet strict aerospace fire safety regulations without compromising passenger safety due to weight increase or performance loss.

• Smart Composites: Integration of sensors and other smart technologies into composite materials for structural heath monitoring thereby enhancing maintenance practices as well as safety protocols.

• Recycling and Circular Economy: Innovations on recycling techniques for composites such as chemical methods which allow for recovery and reuse, supporting the aspirations of a circular economy model within the aerospace industry.

• Customization and Modular Designs: Developments in modularized composites design enables easier customization for aircraft interiors reconfigurations to take place depending on different airline requirements increasing passenger satisfaction.

Strategic Growth Opportunities for Composites in the Global Aerospace Interior Market

Composites in the global aerospace interior market is very dynamic due to its unique properties of being lightweight, strong and thermally stable. Some key strategic growth opportunities for this market include:

Weight Reduction and Fuel Efficiency

• Lightweight Materials: Compared to traditional materials like aluminum and steel, that is heavy, composites come with a significant weight saving. Low weight means an increase in fuel efficiency as well as reduced operational costs; these are important for airliners who want to be more profitable and sustainable.

• Advanced Materials: Fuel consumption can also be further optimized by using new composite materials including carbon fiber-reinforced polymers (CFRP) which have higher strength-to-weight ratios.

Customization and Design Flexibility

• Innovative Designs: Composites provide great design flexibility in manufacturing customized interior components that contribute to the comfort of passengers and aesthetic appeal. Included in this are airline-specific seats, overhead bins, and panels.

• Integrated Features: Composites make it possible for incorporation of complex features like embedded lighting, sensors, and electronic systems among others that enhance customers’ satisfaction during air travel.

Enhanced Durability and Maintenance

• Longer Lifespan: Internal parts made from composites do not wear out easily hence they last longer than others made from different materials. This reduces the need for frequent replacements and maintenance thereby enhancing cost savings for airlines.

• Ease of Repair: There has been improvement in composite repair technology making it easier and faster to repair damages on aircraft parts thus reducing on down time while maintaining operational efficacy.

Sustainability and Environmental Impact

• Eco-friendly Materials: Sustainability is an aspect that is being focused on greatly by the aerospace industry. These include composites produced from raw materials derived from plants or those that can be recycled; this lowers the environmental impact brought about by aircraft interiors.

• Reduced Emissions: Lightweight aircraft cabin reduces fuel intake thereby minimizing greenhouse gas emissions; hence assisting airlines to meet strict environmental regulations as well as attain corporate sustainability goals.

Safety and Performance

• Fire Resistance: Modern composites are designed specifically to meet very stringent fire safety standards thus offering enhanced resistance against fires thereby protecting passengers. This is essential when complying with aviation safety regulations.

• Structural Integrity: Under different stressing conditions, composites maintain high structural integrity which is crucial for the overall safety and performance of commercial aircraft interiors.

Cost Efficiency

• Manufacturing Advancements: Composite manufacturing has seen innovations such as automated fiber placement (AFP) as well as 3D printing that have led to reduction in production cost and time. This makes composite components of high-performance accessible and cost-effective within the aerospace industry.

• Lifecycle Cost Savings: Despite their more expensive initial costs, the durability of composites coupled with reduced maintenance requirements and fuel efficiency gains account for considerable savings over their entire life cycle.

Technological Integration

• Smart Interiors: Integration of smart systems within composite structures enables the development of intelligent cabin systems. These systems are capable of adjusting environmental conditions for increased passenger comfort and operational effectiveness.

• Connectivity: Composites allow smooth integration of sophisticated connectivity solutions such as inflight entertainment and communication systems thus meeting rising demand for connected experiences.

Market Expansion and Collaboration

• New Markets: Emerging markets in particular those in Asia-Pacific and Middle East provide significant growth prospects for composites used in aerospace interiors. The increasing demand for air travel within these regions necessitates innovative interior solutions that are efficient.

• Industry Partnerships: Collaborations between composite manufacturers, leading aerospace firms, research institutions inspire novelty thereby accelerating advances in airplane interiors using advanced composites.

Composites in the Global Aerospace Interior Market Driver and Challenges

The factors responsible for driving the composites in the global aerospace interior market include:

1. Weight Reduction: As opposed to usual materials, composites offer a heavy reduction that leads to low fuel consumption and higher effectiveness of airplanes.

2. Fuel Efficiency: Lighter planes are more economical in terms of fuel allowing businesses to save money and protect the environment.

3. Durability and Longevity: The fact that composites are highly durable and do not corrode significantly reduces costs linked to maintenance while extending the life of components used in an aircraft.

4. Design Flexibility: The complex shapes that composites can take through moulding enable creative interior designs as well as ergonomics.

5. Regulatory Compliance: Stricter laws relating to emissions and ecological degradation have seen adoption of such light weight and efficient materials as composites become popular among manufacturers.

6. Passenger Comfort: By which composites improve passenger comfort with better noise attenuation properties and vibration damping properties.

Challenges in the composites in the global aerospace interior market are:

1. High Production Costs: Manufacturing processes involved with composite materials are often very expensive when compared to those employed for traditional ones.

2. Complex Manufacturing Processes: Composite production can be complicated, time-consuming, requiring special equipment and skilled labor.

3. Repair and Maintenance: Reparation of metals is generally easier than that of composites since they call for specific techniques together with materials.

Composites will play a major role in the worldwide aerospace interior market going forward because of its advantages in terms of weight reduction, fuel efficiency, and design flexibility. However, there are a few obstacles that must be overcome, such as costly production, complex manufacturing, challenging repairs, and recycling. But if technology advances and economies of scale increase, the benefits of using composites might surpass these challenges, which would encourage the aerospace industry to continue adopting and innovating with them.

Composites in the Global Aerospace Interior Suppliers and Their Market Shares

In this globally competitive market, several key players such as Hexcel Corporation, BASF, Solvay, etc. dominate the market and contribute to industry’s growth and innovation. These players capture maximum market share. To know the current market share of each of major players contact us. If you wish to deep dive in competitive positioning of these players then you can look into our other syndicated market report on “Composites in the Global Aerospace Interior leadership report".

Companies in the market compete on the basis of product quality offered. Major players in this market focus on expanding their manufacturing facilities, R&D investments, infrastructural development, and leverage integration opportunities across the value chain. With these strategies aerospace composites in the global aerospace interior companies cater increasing demand, ensure competitive effectiveness, develop innovative products & technologies, reduce production costs, and expand their customer base. Some of the aerospace composites in the global aerospace interior companies profiled in this report include.

• Hexcel Corporation

• BASF

• Solvay

• Gurit

• SGL Carbon

• Toray Industries

• Teijin Limited

These companies have established themselves as leaders in the composites in the global aerospace interior industry, with extensive product portfolios, global presence, and strong research and development capabilities. They continually strive to enhance their market positions through strategic partnerships, mergers and acquisitions, and product innovations.

The market share dynamics within the composites in the global aerospace interior market are evolving, with the entry of new players and the emergence of innovative composites in the global aerospace interior technologies. Additionally, collaborations between material suppliers, manufacturers, and end-users are fostering technological advancements and expanding market opportunities.

Composites in the Global Aerospace Interior Market by Segments

In the worldwide aerospace interior market, there are notable cases of growth in some important composite areas. The cabin interiors made up of seats, panels and overhead compartments have increasingly been embracing lightweight and strong composites in order to enhance fuel efficiency as well as make traveling more comfortable for passenger’s onboard. Another quickly expanding segment under this category is floor panels that utilize high-strength composites to reduce aircraft weight thus improving performance. Increased use of advanced composites in galleys and lavatories can be attributed to their lower weights and ability bend which makes these parts ideal for ingenious designs development. Composites have also found their way into cockpit interiors with better safety features and longer lifespan. Monuments & stowage bins too are becoming popular because airlines want light yet rugged storage solutions which will help them manage space on board planes.

Composites in the global aerospace interior market report provides a comprehensive analysis of the marketÄX%$%Xs current trends, growth drivers, challenges, and future prospects in all major segments like above. The report offers insights into regional dynamics, highlighting the major markets for composites in the global aerospace interior market by application, type, application, manufacturing process, fiber type, resin type and region as follows:

Composites in the Global Aerospace Interior Market by Aircraft Type [Value ($M) and Volume (M lbs) Analysis for 2018 to 2030]:

• Commercial Aircraft

• General Aviation

• Regional Aircraft

• Helicopter

• Military Aircraft

Composites in the Global Aerospace Interior Market by Application [Value ($M) and Volume (M lbs) Analysis for 2018 to 2030]:

• Interior Panels

• Seating

• Galley

• Stowage Bins

• Lavatory

• Others

Composites in the Global Aerospace Interior Market by Manufacturing Process [Value ($M) and Volume (M lbs) Analysis for 2018 to 2030]:

• Prepreg Layup

• RTM

• Others

Composites in the Global Aerospace Interior Market by Fiber Type [Value ($M) and Volume (M lbs) Analysis for 2018 to 2030]:

• Glass Fiber

• Carbon Fiber

• Others

Composites in the Global Aerospace Interior Market by Resin Type [Value ($M) and Volume (M lbs) Analysis for 2018 to 2030]:

• Phenolic

• Epoxy

• Others

Features of the Composites in the Global Aerospace Interior Market

• Market Size Estimates: Composites in the global aerospace interior market size estimation in terms of value ($M) and volume (M lbs) .

• Trend and Forecast Analysis: Market trends (2018-2023) and forecast (2024-2030) by various segments and regions.

• Segmentation Analysis: Global composites in the aerospace interior market size by various segments, such as aircraft type, application, market type, manufacturing process, fiber type, and resin type in terms of value and volume.

• Regional Analysis: Composites in the global aerospace interior market breakdown by North America, Europe, Asia Pacific, and Rest of the World.

• Growth Opportunities: Analysis of growth opportunities in different aircraft type, application, market type, manufacturing process, fiber type, and resin type and regions for composites in the global aerospace interior market.

• Strategic Analysis: This includes M&A, new product development, and competitive landscape of the composites in the global aerospace interior market.

• Analysis of competitive intensity of the industry based on Porter’s Five Forces model.

If you are looking to expand your business in composites in the global aerospace interior or adjacent markets, then contact us. We have done hundreds of strategic consulting projects in market entry, opportunity screening, due diligence, supply chain analysis, M & A, and more.

Frequently Asked Questions (FAQ)

Q1. What is composites in the global aerospace interior market size?

Answer: Composites in the global aerospace interior market is expected to reach an estimated $688 million by 2030.

Q2. What is the growth forecast for composites in the global aerospace interior market?

Answer: Composites in the global aerospace interior market is expected to grow at a CAGR of 4% from 2023 to 2030.

Q3. What are the major drivers influencing the growth of the composites in the global aerospace interior market?

Answer: The major drivers for this market are weight reduction and fuel efficiency.

Q4. What are the major type or end use industries for aerospace composites in the global aerospace interior?

Answer: Commercial aircraft is the major segment by aircraft type for aerospace composites in the global aerospace interior.

Q5. What are the emerging trends in composites in the global aerospace interior market?

Answer: Emerging trends, which have a direct impact on the dynamics of the industry, include increased use of thermoplastic composites, adoption of nano-composites, advancement of 3D printing, developing hybrid composites, and integration of smart composites.

Q6. Who are the key composites companies in the global aerospace interior market?

Answer: Some of the key aerospace composites companies in the global aerospace interior market are as follows:

• Hexcel Corporation

• BASF

• Solvay

• Gurit

• SGL Carbon

• Toray Industries

• Teijin Limited

Q7. Which aerospace composites in the global aerospace interior, which application segment will be the largest in future?

Answer: Lucintel forecasts that interior panels will remain the largest application

Q8. In composites in the global aerospace interior market, which region is expected to be the largest in next 7 years?

Answer: North America is expected to remain the largest region due to largest number of aircraft OEMs in this region.

Q9. Do we receive customization in this report?

Answer: Yes, Lucintel provides 10% Customization Without any Additional Cost.

This report answers following key questions

Q.1 What are some of the most promising, high-growth opportunities for composites in the global aerospace interior market by aircraft type (commercial aircraft, regional aircraft, general aviation, helicopter, and military aircraft), by application (interior panels, seating, galley, stowage bin, lavatory and others), by manufacturing process (prepreg layup, RTM and Others), By fiber type (glass fiber, carbon fiber and others), By resin type (phenolic, epoxy and others) and by region (North America, Europe, Asia Pacific, and the Rest of the World)?

Q.2 Which segments will grow at a faster pace and why?

Q.3 Which region will grow at a faster pace and why?

Q.4 What are the key factors affecting market dynamics? What are the drivers and challenges in this market?

Q.5 What are the business risks and threats of this market?

Q.6 What are emerging trends in this market and reasons behind them?

Q.7 What are some of the changing demands of customers in the market?

Q.8 What are the new developments in the composites in the global aerospace interior market? Which companies are leading these developments?

Q.9 Who are the major players in this market? What strategic initiatives are being implemented by key players for business growth?

Q.10 What are some of the competitive products and processes in this composite in the global aerospace interior market area and how big of a threat do they pose for loss of market share via material or product substitution?

Q.11 What M&A activity has occurred in the last 5 years?